China has established itself as the global leader for plastic injection mold maker services, with over 30,000 manufacturing firms specializing in high-volume production. When businesses need to find mold maker in China, they discover a manufacturing ecosystem that produces nearly 25% of all plastic molds worldwide. The combination of advanced technology, competitive pricing, and proven expertise makes China the top destination for companies seeking a reliable plastic mold maker in China.

Global manufacturers—from emerging startups to Fortune 500 companies—consistently choose a China mold maker for their speed, scale, and technical capabilities. Industries spanning automotive, electronics, and medical devices rely on Chinese suppliers for everything from rapid prototyping to mass production. The efficiency, design flexibility, and rigorous quality controls (including ISO-certified facilities) position the best mold maker in China as essential partners for demanding, high-quantity manufacturing needs.

Modern factories across China leverage smart manufacturing, advanced CNC machining types, and comprehensive quality systems to deliver consistent results with rapid turnaround times. For businesses aiming to scale quickly and compete globally, a plastic injection mold maker China partnership provides the expertise, capacity, and cost advantages necessary to drive business growth.

Key Advantages of Choosing a Plastic Injection Mold Maker in China

When you need to find mold maker in China for large-scale production, the country consistently leads due to its unique combination of competitive costs, scalable technology, and proven quality standards. Selecting a plastic mold maker in China positions your business for efficiency and reliability that surpasses most global alternatives. Here’s why manufacturers worldwide choose China for mass production mold services.

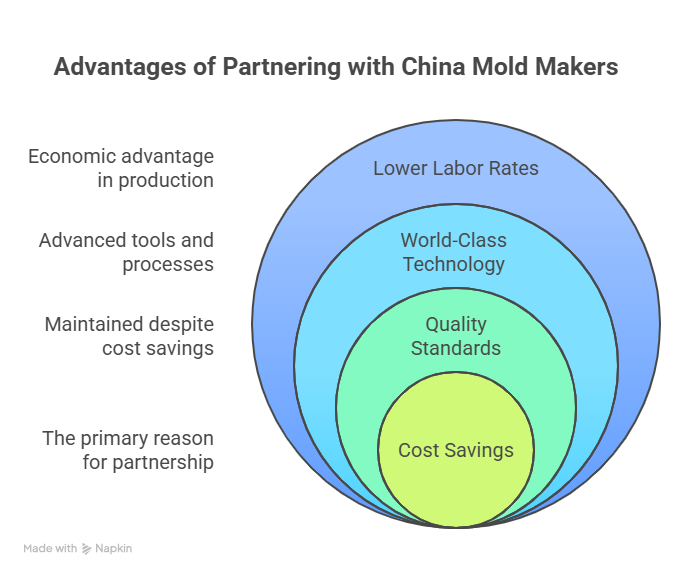

Cost Efficiency Compared to Global Alternatives

The primary reason companies partner with a China mold maker for large orders is straightforward: significant cost savings without compromising quality standards. The best mold maker in China facilities offer world-class technology and engineering at labor rates substantially lower than Western markets.

Key cost advantages include:

- Labor costs significantly lower than US, European, or Japanese rates

- Economies of scale that reduce prices as order volumes increase

- High competition within China maintaining competitive pricing and elevated service standards

This cost efficiency doesn’t require quality compromises. Many companies discover that top-tier plastic injection mold maker China facilities produce molds at less than half the cost of Western suppliers while maintaining stringent quality standards.

Production Capacity, Scale, and Lead Times

When speed and scale are critical, a plastic mold maker in China delivers unmatched capabilities. Leading suppliers operate enormous facilities equipped for massive production runs—whether you need thousands or millions of cycles.

Production advantages include:

- Rapid scaling: Chinese manufacturers quickly increase production by adding shifts or reallocating workforce

- Flexible lead times: Common to see lead times 50% shorter than US or Japanese competitors

- Unmatched capacity: China accounts for nearly one-fourth of global plastics production

This capacity means faster part delivery—even for urgent, high-quantity orders. The infrastructure supporting plastic injection mold maker services in China enables rapid response to changing market demands.

International Quality and Certification Standards

The best mold maker in China understands that global companies require superior products. Leading factories invest heavily in quality control systems and align with international standards including ISO, CE, and RoHS certifications.

Quality assurance features:

- Advanced factory testing: Top suppliers utilize sophisticated measurement tools and inspection systems

- Transparent auditing: Clients receive quality reports at every major production milestone

- Trusted certifications: Leading manufacturers maintain ISO certification and frequently meet CE and RoHS export requirements

Working with a trusted China mold maker provides substantial cost savings, fast delivery, and confidence that each part meets international quality standards.

Specializations and Core Capabilities of Leading Chinese Mold Manufacturers

The best mold maker in China facilities demonstrate proven track records handling large orders with exceptional precision and speed. Their capability to manage everything from complex single-order prototypes to ongoing mass production runs builds on advanced technology, technical expertise, and industry-focused commitment. Let’s examine what distinguishes these manufacturers and how they manage high-quantity production for global clients.

Advanced Technologies: CAD/CAE/CAM, Rapid Prototyping, and Automation

Plastic injection mold maker China suppliers invest heavily in technology and process control to maintain leadership in mass production. The utilization of CAD (Computer-Aided Design), CAE (Computer-Aided Engineering), and CAM (Computer-Aided Manufacturing) software is standard across top-rated facilities, enabling:

- Rapid design and refinement of complex mold geometries

- Simulation and testing of designs for functionality and durability before manufacturing

- Streamlined tool paths for precision machining

Beyond powerful design technologies, rapid prototyping and advanced automation are expected in the finest facilities. 3D printing allows product teams to create prototypes in hours rather than days. Automated machinery accelerates production, reduces labor costs, and minimizes errors.

Many factories have invested in robotics and IoT systems for enhanced tracking, maintenance, and process optimization. These technological advances represent the cutting edge of what a plastic mold maker in China can offer.

Types of Molds and Volume Capabilities

China’s factories produce every type of mold imaginable—from standard plastic injection tools to metal stamping and die casting systems. Whether you need a simple single-cavity tool or a high-cavitation, multi-part system for producing millions of pieces, proven solutions exist.

Common mold types include:

- High Cavitation Molds: Designed for rapid, high-quantity production runs

- Family and Multi-cavity Molds: Multiple parts produced simultaneously for maximum efficiency

- Hot Runner and Cold Runner Molds: Each system optimized for specific volume and complexity requirements

- Large-Scale Molds: For products like automotive panels, appliance housings, and industrial components

Top suppliers routinely handle volumes from small batches to millions of shots per tool. When you find mold maker in China, you discover capabilities spanning the entire production spectrum.

Industry Focus: Automotive, Consumer Electronics, Medical, and Beyond

Leading China mold maker facilities don’t serve just one sector—they excel across industries where high-volume, high-precision production is essential. Their core strengths align with industries demanding repeatability and consistency.

Major industry applications include:

- Automotive: Components like dashboards, bumpers, connectors, and interior trim requiring tight tolerances and extended tool life

- Consumer Electronics: Casings, screens, battery housings, and connectors produced at scale for major brands

- Medical: Devices, enclosures, and single-use items manufactured in cleanroom environments with rigorous quality control

- Household Appliances: From washing machine components to refrigerator parts

What distinguishes the best mold maker in China in these sectors? Years of investment in quality systems, ISO-certified facilities, and commitment to maintaining current industry standards. This specialized technical support for highly regulated and fast-moving industries gives importers confidence to produce everything from critical medical components to complex electronics in high volumes while maintaining consistent quality.

How to Select a Reliable High Production Mold Supplier in China

Choosing a dependable plastic injection mold maker in China can determine your high-volume project’s success or failure. From consistent quality to real-time project updates, the right partner saves time, money, and eliminates complications. Here’s how to identify a supplier you can trust for mass production.

Vetting Supplier Quality and Facility Standards

Never skip evaluating a supplier’s quality controls and facility standards. Here’s how to ensure you’re working with a professional plastic mold maker in China:

- Request certifications like ISO 9001—top suppliers understand and meet global benchmarks

- Visit facilities in person or via video call, looking for clean, organized facilities with modern equipment and in-process quality checks

- Demand detailed sample reports and testing data—solid suppliers provide clear evidence of past quality work on similar molds

- Question quality protocols—Do they use advanced inspection equipment? How are defects managed?

Thorough vetting prevents costly mistakes. The best mold maker in China welcomes scrutiny and provides transparent answers about their quality systems.

Ensuring Intellectual Property Protection and Confidentiality

Protecting your designs, molds, and proprietary information should be your highest priority. Smart IP protection strategies include:

- Use China-specific NNN agreements (Non-Disclosure, Non-Use, Non-Circumvention)—standard Western NDAs provide insufficient protection in China

- Register patents, trademarks, and copyrights locally—protection in your home country rarely covers China

- Define mold ownership in writing—specify who owns the mold, storage location, and procedures if you change suppliers

- Secure file transfers—avoid public file-sharing sites and limit access to sensitive information

- Discuss IP protection openly before signing any agreements

When you find mold maker in China, ensure they understand and respect intellectual property protection requirements.

Communication, Language, and Project Management

Effective communication bridges the gap between you and your China mold maker—crucial for smooth large-order projects.

Communication best practices:

- Keep instructions clear and concise—use simple English and visual guides when helpful

- Confirm details in writing—deadlines, quality requirements, and follow-up procedures

- Understand project management systems—Do they assign dedicated account managers? Are regular updates standard?

- Establish direct communication channels—email and WeChat for faster responses

- Ask direct questions when anything appears unclear

Suppliers struggling with communication may cause missed specifications or delayed deadlines. Getting communication fundamentals right establishes the foundation for a successful, long-term partnership with your chosen plastic injection mold maker China.

Trends and Innovations in High Quantity Mold Making in China

China is transforming high-quantity and high-volume mold operations. Top suppliers aren’t simply producing parts—they utilize smart digital tools, provide transparent updates, and implement sustainable processes that deliver new levels of reliability and value to global clients. By combining factory-direct service models with increased sustainability focus, the best mold maker in China leads industry transformation in how large orders are managed, monitored, and delivered.

Digital Integration and Transparent Project Updates

Digital transformation forms the foundation for smoother projects and fewer surprises in the Chinese mold industry. Leading plastic injection mold maker facilities use integrated CAD/CAM/CAE platforms, digital dashboards, and real-time tracking systems. These tools enable clients to:

- Monitor project milestones and material status in real-time

- Receive instant feedback on design modifications or engineering changes

- Download inspection reports, 3D models, and test data from cloud-based portals

Factories deploy software for live schedule tracking, giving buyers greater control over large orders. Artificial intelligence and automation further reduce errors and accelerate lead times. Transparency has become a competitive advantage—clients want trustworthy updates, not vague promises.

Top plastic mold maker in China suppliers offer factory floor cameras, secure file sharing, and regular progress reports, ensuring you maintain project visibility regardless of geographic distance.

Emphasis on Sustainability and Green Manufacturing

Eco-friendly mold making takes center stage as China’s factories balance mass production with global sustainability objectives. China mold maker facilities are:

- Investing in high-efficiency machinery consuming less energy

- Recovering and recycling plastics and metals during production

- Selecting non-toxic lubricants and coolants

- Implementing cleaner waste and emission controls

High quantity production doesn’t require high waste levels. Top suppliers now design molds for extended life, reducing frequent rebuilds and minimizing raw material consumption. Some facilities use renewable energy to power operations partially or completely.

Simple improvements like reusable packaging or optimized cycle times for reduced scrap accumulate significant benefits when producing millions of parts. The best mold maker in China demonstrates that environmental responsibility and high-volume production can coexist effectively.

Factory-Direct Models vs. Brokered Orders

For high-volume orders, choosing between direct factory partnerships and brokered arrangements significantly impacts results.

Factory-direct partnerships are increasing because buyers prefer:

- Direct communication with engineers and project managers

- Faster response times and easier troubleshooting

- Lower total costs (eliminating third-party markups)

- Greater visibility into production schedules and potential issues

Digital communication tools and cloud-based platforms make overseas project management from the factory floor easier than ever.

Brokered orders involve agents or sourcing companies as intermediaries. While convenient, this approach sometimes creates slower feedback, higher prices, and reduced transparency. For large, ongoing orders, the direct approach typically delivers more consistent results.

Modern buyers value speed, clarity, and personal attention. The direct factory model, supported by transparent updates and technology-driven workflows, rapidly becomes the standard for high-quantity mold making in China.

TK Mold: Shenzhen’s High Volume Mold Manufacturing Leader

TK Mold, headquartered in Shenzhen, represents one of China’s most established plastic injection mold maker companies. With decades of experience and technical excellence focus, TK Mold excels at handling large orders with precision and speed. Companies worldwide partner with TK Mold for mass production requirements in automotive, appliances, electronics, and other demanding industries. Here’s why TK Mold earns trust from global brands and makes mass production stress-free for buyers.

Large-Scale Capacity With Proven Track Record

TK Mold operates at unmatched scale. The group manages multiple production bases in key manufacturing hubs including Shenzhen, Huizhou, and Suzhou, with over 180,000 square meters of facilities. This means sufficient space and machinery to deliver enormous, ongoing orders on schedule—whether you need 50,000 units or several million.

Capabilities include:

- Project management of any size, from small batches to long-term contracts

- Dedicated production lines for automotive, consumer, and home appliance components

- Highly trained technical teams focused on maintaining consistent quality

Clients depend on TK Mold for everything from complex automotive interior molds to sleek plastic housings for home and industrial devices. Their established systems maintain optimal production pace even under tight deadlines.

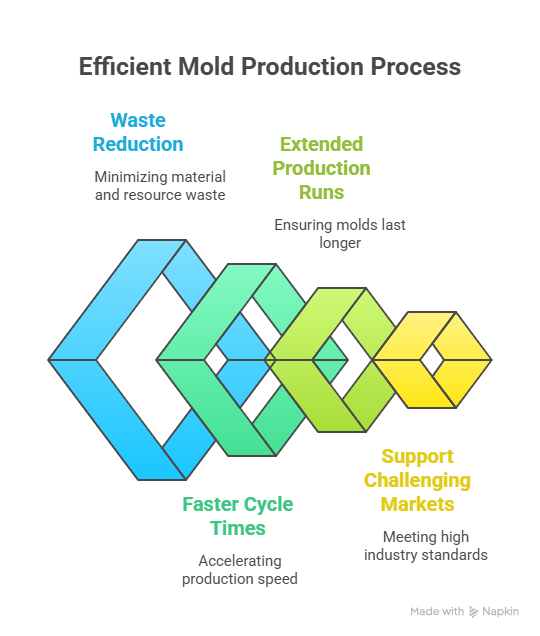

Technical Strength and Advanced Equipment

TK Mold employs advanced design systems and manufacturing equipment throughout every production stage:

- State-of-the-art CAD/CAM/CAE tools maximizing design accuracy and part quality

- Modern CNC, EDM, and high-precision measuring equipment achieving tight tolerances

- Skilled engineers monitoring every phase from initial tool making to final mold approval

The result is reduced waste, faster cycle times, and molds built for extended production runs. This technical approach enables TK Mold to support even the most challenging and regulated markets, including automotive and electronics. Their efficient manufacturing processes allow short lead times even on complex or high-cavity projects.

Focus on Quality, Certifications, and Client Transparency

TK Mold doesn’t just pursue speed—they support it with reliable, certified quality control. Their processes align with international standards, and each order receives testing and traceability from first shot to final packaging:

- Strong ISO-based management maintaining high standards on every project

- Advanced inspection procedures and digital traceability for complete transparency

- Ongoing technical support before, during, and after mold delivery

This process and detail focus means TK Mold clients receive clear updates, problem-solving support, and complete peace of mind. When challenges arise, the team responds quickly with clear communication about developments.

Ready to Support Your Next Project

TK Mold combines personalized attention with the scale and expertise of a major player in China’s molding industry. If your project requires reliable capacity, consistent quality, and a dedicated team that delivers results, consider reaching out. Contact brandon@tkmold.com to discuss your next high-volume mold project or request a quote. Let’s ensure you achieve results that meet your objectives every time.

Contact our Technical Sales Support Manager today to discuss your next project! brandon@tkmold.com

Conclusion

China continues setting the global pace for high-volume mold manufacturing. The combination of technical advancement, skilled teams, and unmatched production scale drives results for buyers across every major industry. Advanced automation, digital project tracking, and continuous improvements in mold materials elevate quality while maintaining short lead times.

Ongoing investment in smart manufacturing and real-time factory monitoring makes large orders dependable and efficient. Chinese factories already utilize predictive analytics and deeper supply chain integration, reducing downtime and ensuring more consistent parts.

As precision and sustainability demands grow, the best mold maker in China adapts quickly—offering greener processes, longer-lasting tools, and flexible service for global brands. Coming years will bring even tighter production control and faster responses to shifting market requirements.

Partnering with a proven plastic injection mold maker China gives your business the competitive edge for growth. When you find mold maker in China that matches your needs, you tap into the experience and capacity these manufacturers have developed. If you’re ready for reliable scale and technology-driven results, now is the time to begin your next project with a trusted plastic mold maker in China team.