Your Trusted Injection Molding Offshore Tooling Partner.

Navigate global tooling with confidence. We manage your offshore injection mold projects end-to-end—from supplier vetting to on-site qualification—delivering cost savings without compromising quality.

01

01 02

02 03

03Proudly Serving Industry Leaders

Trusted by Fortune 500 manufacturers and innovative startups worldwide to deliver precision engineering and manufacturing excellence.

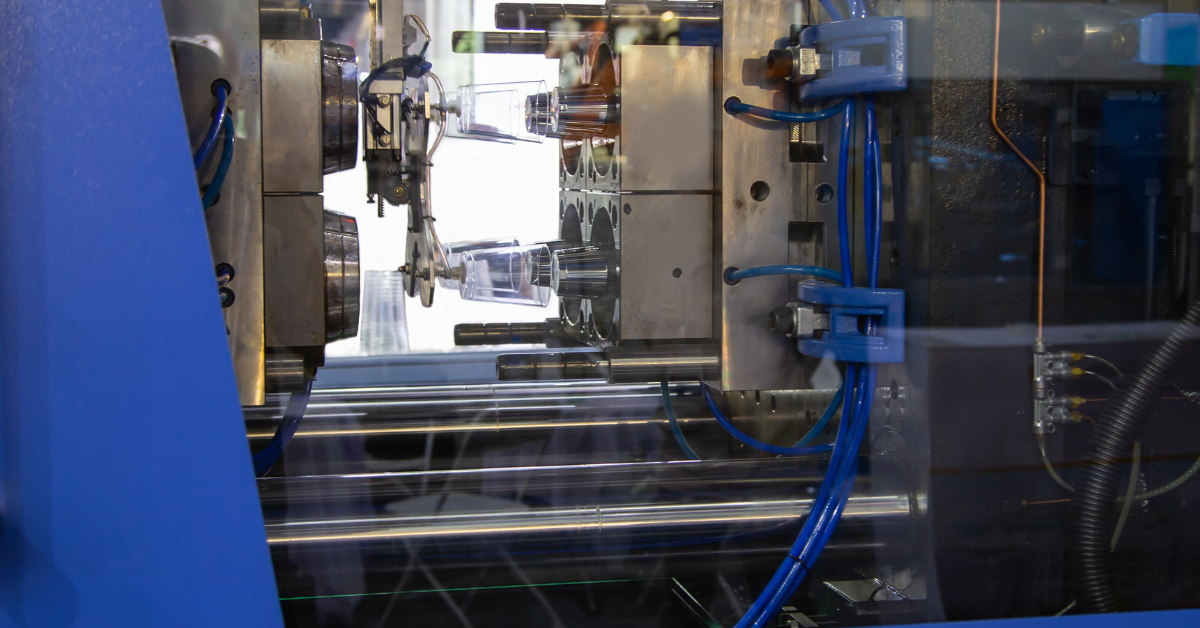

End-to-End Injection Molding Services for Smarter, Faster Manufacturing

MoldMinds delivers plastic part design, moldflow analysis, tooling and molding project management, and injection molding consulting to help you optimize performance, reduce costs, and bring quality parts to market faster.

Injection Molding Consulting

Expert guidance to optimize part design, material selection, and tooling strategy for efficient, defect-free molding.

Injection Molding & Tooling Project Management

End-to-end oversight from design to production, ensuring your molds are built right, on time, and on budget.

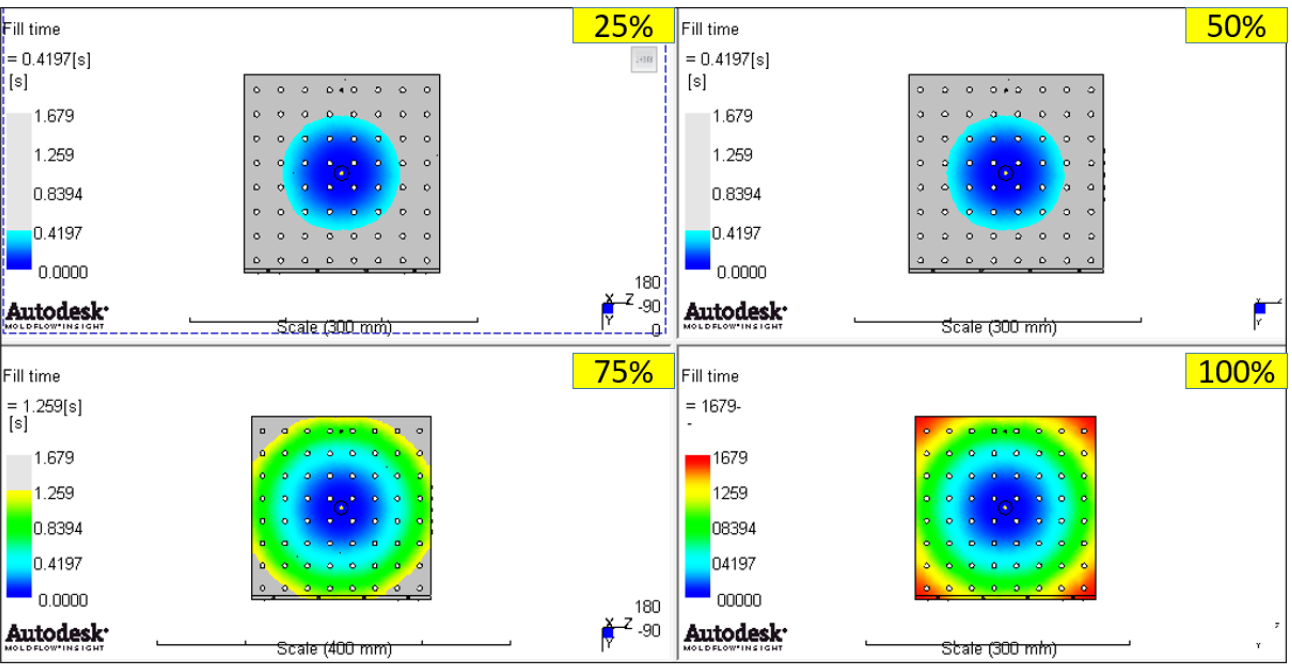

Moldflow Analysis

Advanced simulation to predict flow behavior, eliminate defects, and achieve high-performance mold designs before cutting steel.

Plastic Part Design

Precision-engineered part design focused on manufacturability, strength, and cost-effective production.

Why Manufacturers Choose MoldMinds

We combine engineering precision with digital manufacturing expertise to deliver faster, more reliable outcomes every time.

Engineering-Driven Expertise

Experienced engineers and moldflow specialists guide each project from concept to production, ensuring manufacturable, high-performance designs.

Transparent Project Management

End-to-end project oversight with clear timelines, real-time updates, and complete accountability from CAD to production.

Cost & Quality Optimization

Data-informed analysis reduces rework, shortens tooling cycles, and ensures exceptional part quality without exceeding budgets.

Global Manufacturing Network

Access trusted tooling and production partners worldwide, offering scalable sourcing options and seamless delivery.

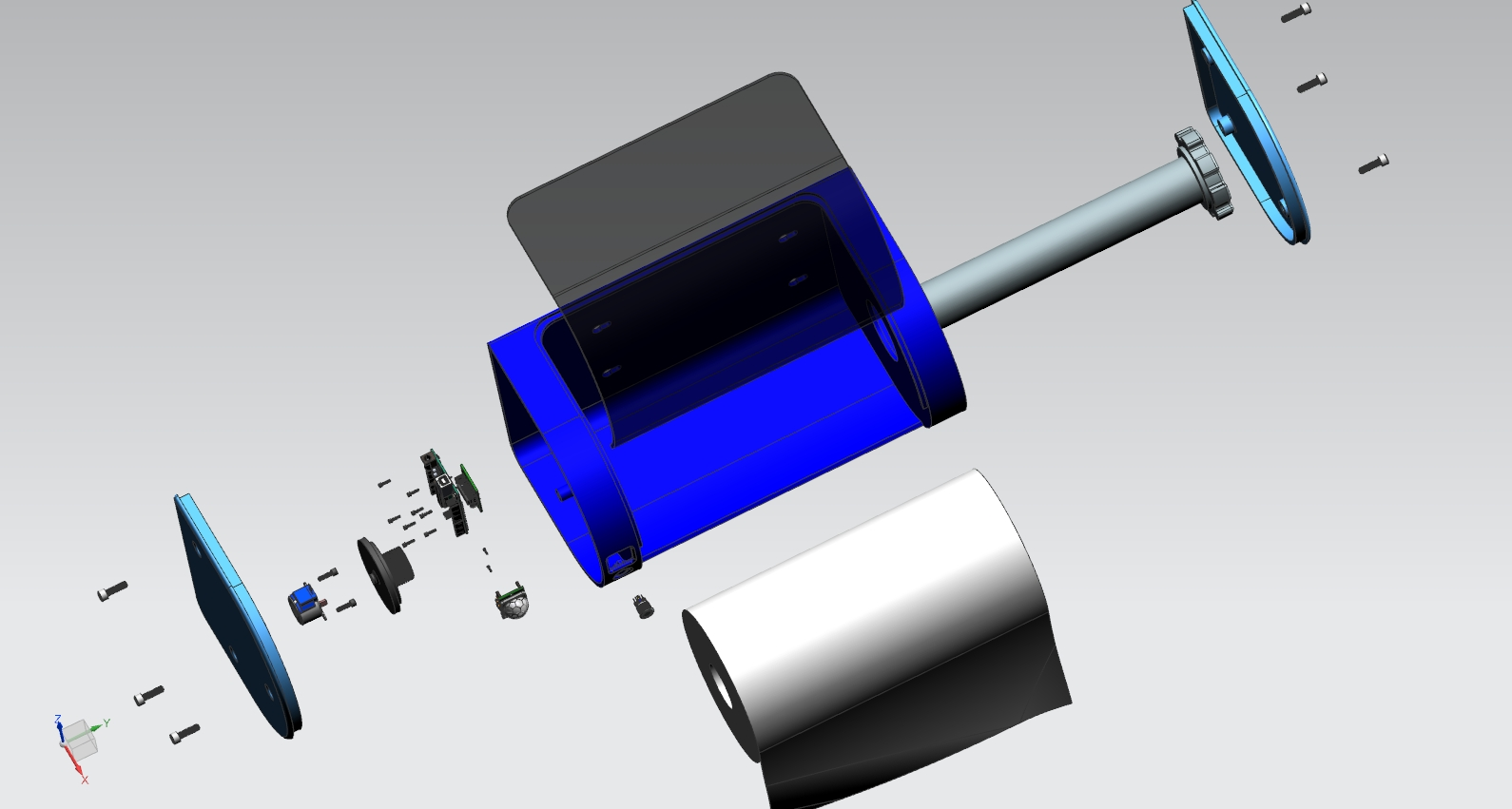

A Look at Our Past Projects

We partner with manufacturers to turn complex challenges into production-ready solutions. Here are a few examples of our work, from initial part design and simulation to final mold engineering. Our process focuses on leveraging advanced tools like Moldflow analysis and rigorous DFM principles to de-risk your project, optimize tooling, and ensure a seamless path from concept to a high-quality, manufacturable part.

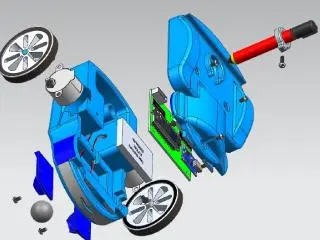

Electronic Enclosure Design

DFM optimization for an electronic toy ensuring durability and cost-effective assembly.

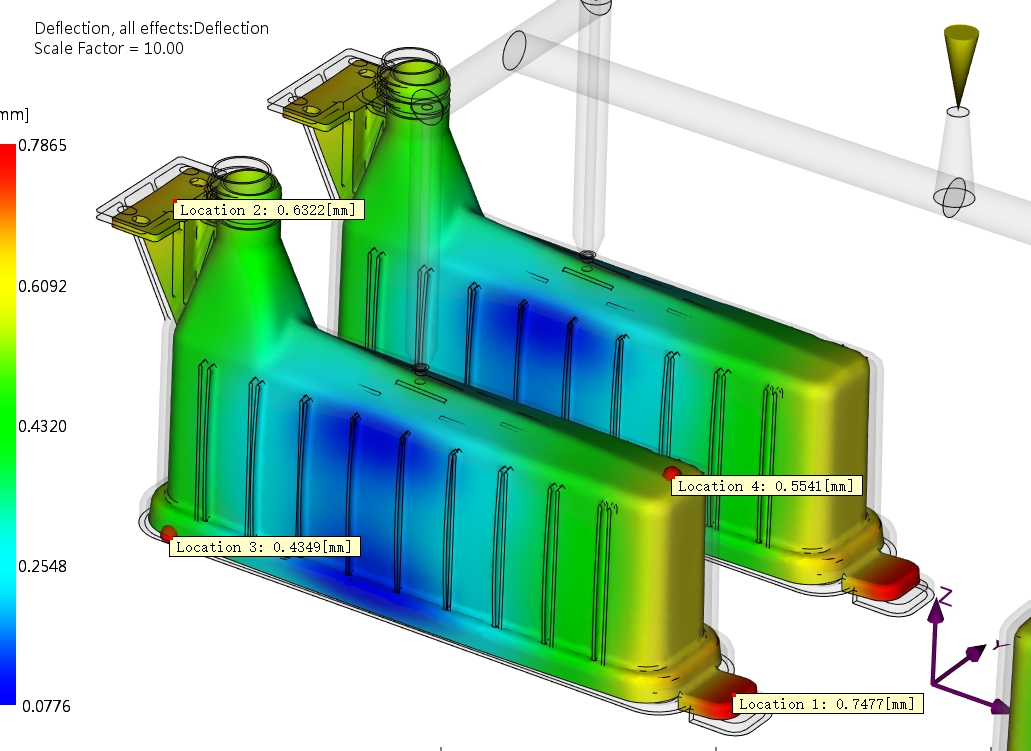

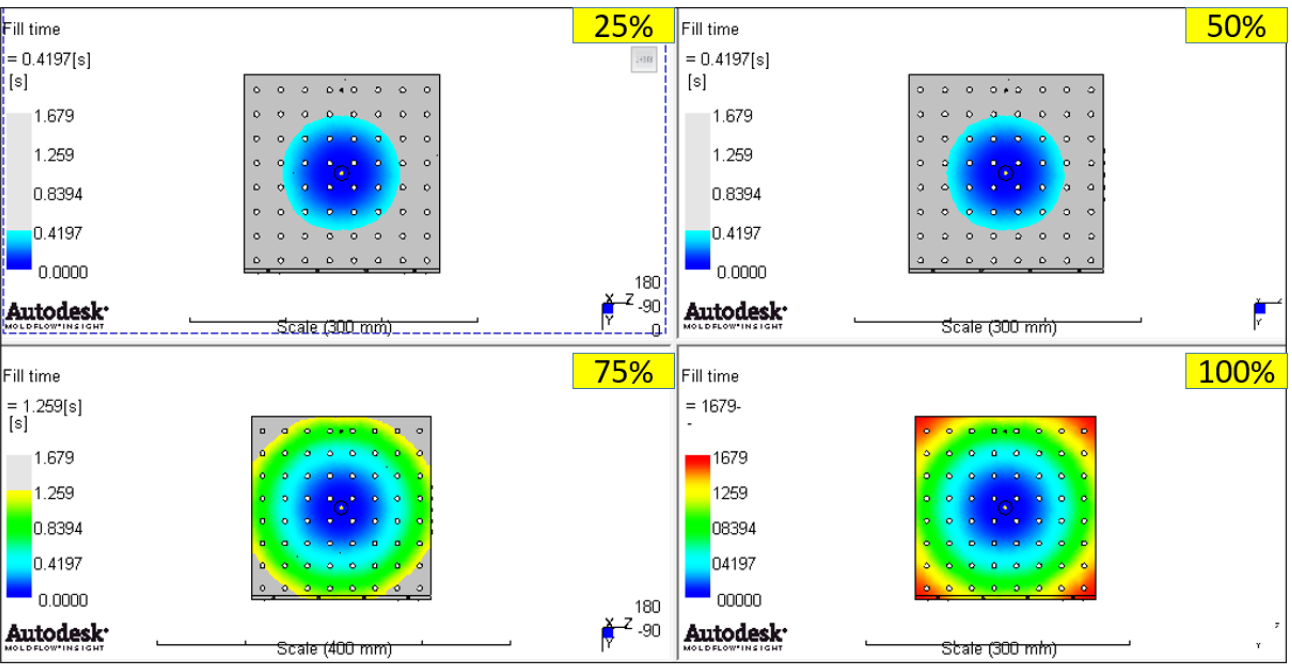

Moldflow Analysis

Flow simulation ensuring balanced fill and minimized defects.

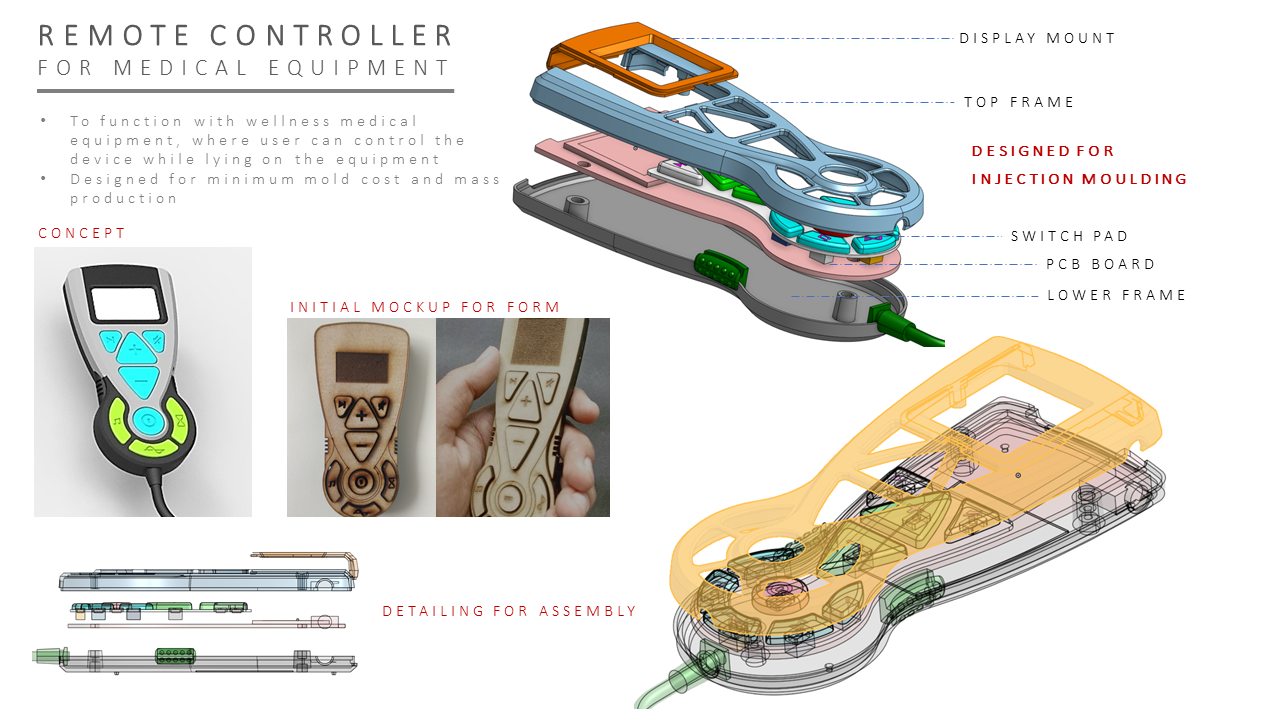

Remote Control Design

Ergonomic design optimized for injection molding.

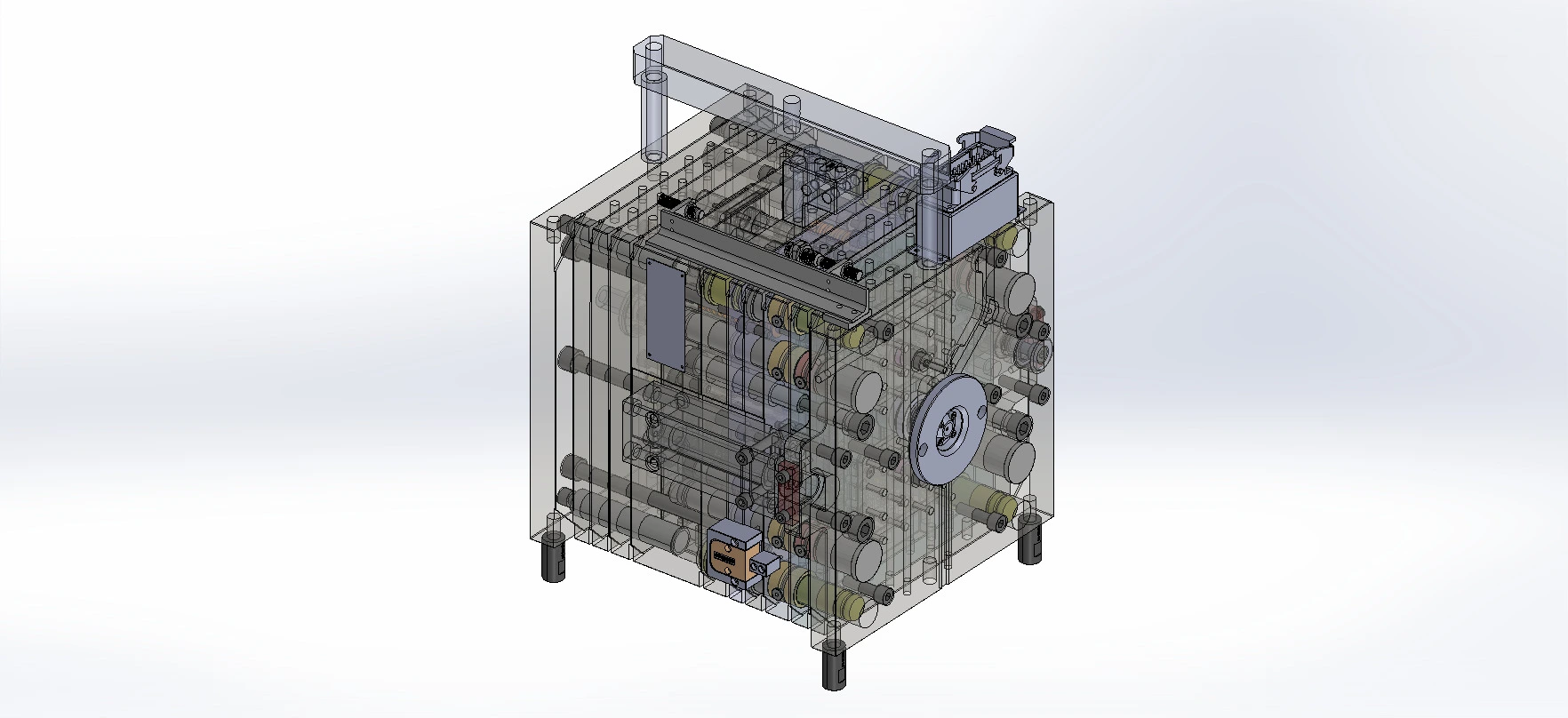

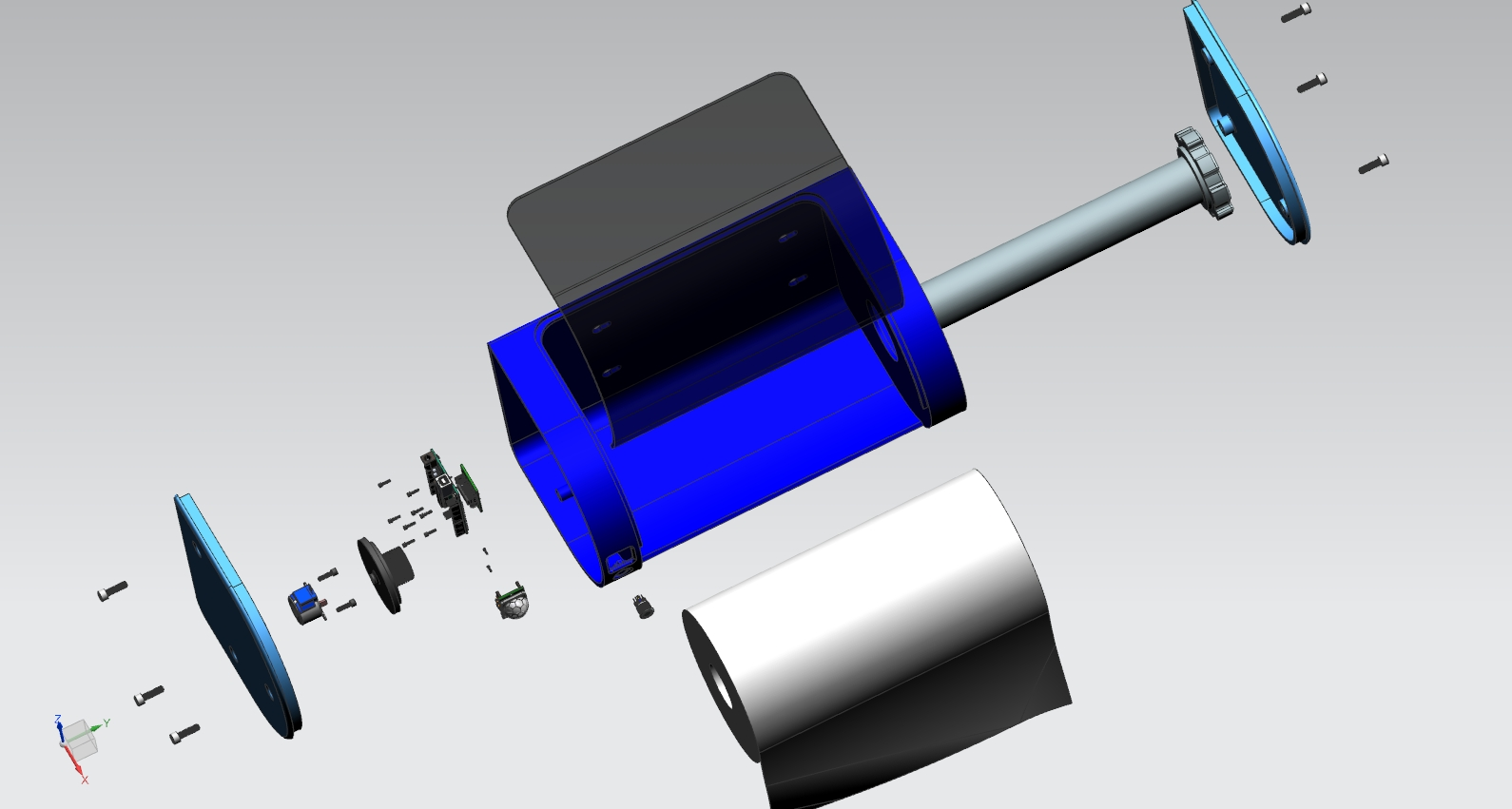

Injection Mold Design

End-to-end mold design using advanced DFM and CAD tools.

Advanced Moldflow Simulation

Precision analysis for optimal cooling and fill patterns.

Plastic Part Design

High-quality plastic component design ready for scalable production.

Trusted by Industry Leaders

We're proud to be the trusted engineering partner for manufacturers who demand precision and reliability.

"

"Amazing service and support, always a fast response time, will definitely use them again!"

Emily Hoskins

CEO, AGNONETWORKS

"

"MoldMinds' DFM analysis on our new enclosure was a game-changer. They identified a critical sink mark issue and a complex undercut that our original design missed. Their recommendations simplified the tool and saved us weeks of rework."

Mark Chen

Sr. Project Engineer, Automotive Tier 1

"

"As a startup, we had to get our part design right the first time. The Moldflow simulation reports from MoldMinds were the most detailed we've ever seen. They gave us the confidence to cut steel, and we nailed our first-shot approval."

Sarah Jenkins

Product Design Lead, Medical Device Startup

"

"We've used other consultants, but MoldMinds is the first to feel like a true extension of our team. They handled our complex multi-cavity tool build with an overseas vendor, and their project management was flawless. They were on time, under budget, and the tool is perfect."

David Rodriguez

Operations Manager, Consumer Products Inc.

Injection Molding Insights & Manufacturing Expertise

Discover data-driven strategies, engineering best practices, and industry innovations that help manufacturers optimize tooling, reduce costs, and accelerate production timelines.

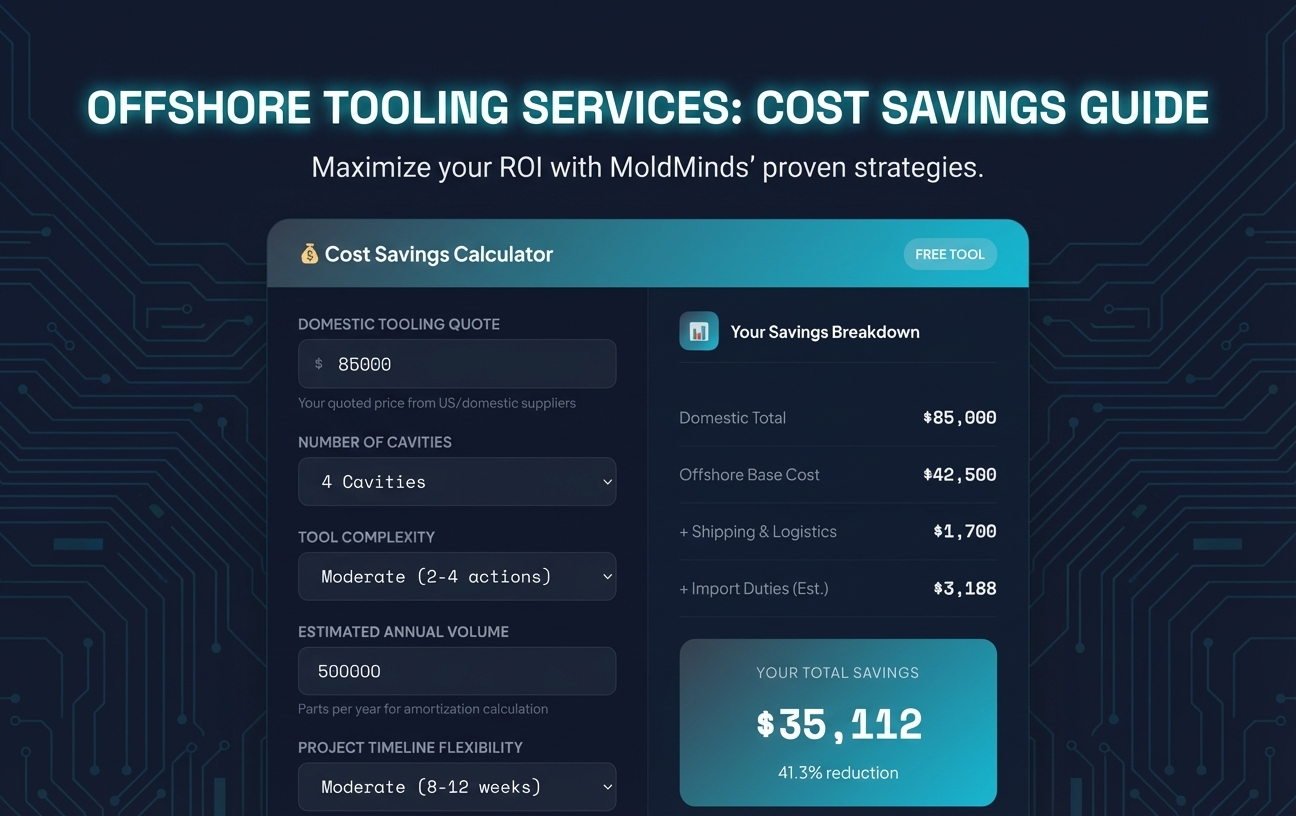

Visit Our BlogOffshore Tooling for Injection Molding: Complete Cost Savings Guide

China vs USA Injection Mold Costs 2025: The Definitive Comparison

Offshore Tooling for Injection Molding: Complete Cost Savings Guide 2025

How to Source Injection Molds from China – Complete Guide

Top 10 Plastic Injection Mold Manufacturers in China (2025 Update)

HDPE vs LDPE: Key Differences for Engineers, Mold Designers & Buyers

Ready to Accelerate Your Next Injection Molding Project?

Partner with engineering-driven experts to eliminate costly design mistakes, shorten tooling lead times, and launch faster with precision.

US$387 B+

Global market size in 2023

4.2% CAGR

Industry growth through 2032

95% +

First-shot success with DFM reviews

Every week of delay can cost thousands in missed production. Let our consultants review your design and ensure your tooling investment performs flawlessly from day one.

Request a Quote