A recent report from the National Institute of Standards and Technology shows that computer-controlled systems can cut production mistakes by as much as 90% compared to manual work. This big improvement in accuracy has changed industries like aerospace and medical devices. In these fields, being off by even a micron can cause a part to fail. CNC machining types play a key role in this shift, offering higher precision and fewer errors in the final product.

Modern manufacturing thrives on accuracy, and computer numerical control delivers it. By translating digital designs into exact physical parts, these systems eliminate human guesswork. Advanced programming guides tools to carve, drill, or shape materials like titanium or composites with microscopic precision.

What makes this technology indispensable? Consistency. Whether producing 10 units or 10,000, every item matches the original blueprint perfectly. From automotive prototypes to custom orthopedic implants, businesses rely on this repeatability to maintain quality and reduce waste.

Key Takeaways

- Computer-controlled systems achieve near-flawless accuracy in production

- Automated processes enable complex designs previously deemed unmanufacturable

- Consistent output quality reduces material waste by up to 35%

- Multiple machine varieties exist for specific materials and applications

- Programming advancements continue to expand manufacturing possibilities

Introduction: The CNC Machining Revolution

The transformation from manual workshops to digital factories began with a breakthrough in 1950s MIT labs. Engineers replaced hand-cranked levers with punch-card systems, creating the first programmable production tools. This innovation laid the groundwork for today’s automated factories where digital blueprints drive physical results.

CNC Technology Overview

At its core, these systems rely on three pillars: control units interpreting design files, precision motors executing movements, and cutting tools shaping raw materials. CAD software transformed design processes by letting engineers create 3D models instead of hand-drawn sketches. “The shift to digital design cut prototype development time by 70%,” notes a manufacturing journal.

Historical Evolution and Modern Impact

Early numerical controls in the 1940s required manual programming via dials and switches. By the 1980s, microprocessor advancements enabled real-time adjustments during operations. Today’s variants handle everything from aircraft turbines to smartphone components with repeatable accuracy under 0.001 inches.

Industries now achieve what was once impossible. Medical device makers produce custom bone implants in hours rather than weeks. Automotive plants maintain 95% reduction in part defects compared to 1970s assembly lines. This evolution continues as smarter software merges with cutting-edge hardware.

Unparalleled Accuracy and Efficiency in CNC Machining

The marriage of digital controls and mechanical precision has redefined production standards globally. Advanced systems now achieve tolerances tighter than a human hair, ensuring components fit perfectly every time. This level of exactness proves vital for applications like aerospace engines and medical implants.

Computerized operations eliminate human error through programmed tool paths. High-speed cutting tools spin at 20,000+ RPM, carving materials faster than traditional methods. One automotive supplier reduced part cycle times by 40% using these rapid systems.

Material removal reaches new efficiency levels with smart chip management. Sensors monitor tool wear, automatically adjusting feeds to maintain ±0.0002″ tolerances. This optimization prevents waste while ensuring part consistency across large batches.

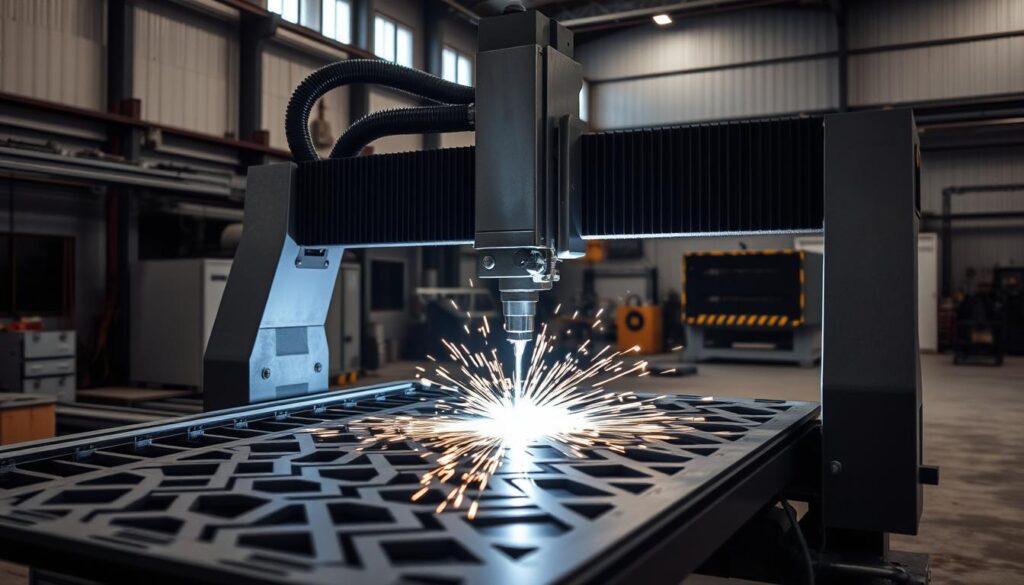

Modern facilities combine milling machines with plasma cutting solutions for diverse material needs. A single setup can handle aluminum prototyping and steel plate fabrication. “The flexibility lets us tackle complex orders without sacrificing speed,” explains a manufacturing engineer at a Chicago plant.

Balancing velocity and exactness drives industry progress. Companies that master this duality lead their markets, delivering quality products at competitive speeds.

Understanding CNC Machining Types for Custom Manufacturing Solutions

Selecting the right equipment makes the difference between mediocre and exceptional product quality. Modern facilities utilize specialized systems designed for specific materials and design complexities. Each variant excels in particular applications, from mass-producing automotive parts to crafting delicate medical instruments.

Overview of Key Machine Types

Industrial routers handle large-scale material carving with speed, ideal for creating signage or furniture components. CNC milling systems dominate metalworking shops, using multi-axis movement to shape engine blocks and aerospace brackets. Lathes rotate materials against stationary cutting tools, perfect for producing symmetrical parts like hydraulic fittings.

| System | Strength | Material Compatibility | Typical Output |

|---|---|---|---|

| Plasma Cutters | High-speed metal slicing | Steel, aluminum | Structural frames |

| Laser Systems | Micro-precision etching | Acrylic, titanium | Medical implants |

| 3D Mills | Complex contours | Composites, alloys | Mold cavities |

Surface finish quality directly impacts product performance and aesthetics. Diamond-tipped cutting tools in CNC milling operations can achieve mirror-like polish on surgical instruments. Laser cutting minimizes heat distortion, preserving material integrity in electronics manufacturing.

Automotive manufacturers rely on five-axis mills for transmission components requiring ±0.0001″ tolerances. Jewelry designers use micro-laser systems to engrave intricate patterns on precious metals. Matching system capabilities to project requirements ensures optimal results across industries.

Deep Dive into CNC Milling Techniques

Rotating tools dance across metal surfaces, sculpting components with microscopic accuracy. This mechanical ballet forms the heart of modern subtractive manufacturing processes. By systematically removing material from solid blocks, these systems transform raw stock into intricate parts for critical applications.

The CNC Milling Process Explained

Operators begin by securing workpieces to machine beds. Cutting tools then follow programmed paths, shaving off layers to reveal desired geometries. End mills excel at creating slots and pockets, while face mills produce flat surfaces. Drill bits penetrate materials vertically, forming precise holes for assembly points.

Advanced control systems enable three-dimensional shaping through simultaneous multi-axis movement. Five-axis configurations let tools approach workpieces from any angle. This capability proves essential for turbine blades and orthopedic implants requiring organic curves.

Tool Variations and Applications in Complex 3D Shaping

Ball-nose cutters carve smooth contours for mold making, while tapered tools reach tight spaces in engine components. Aerospace manufacturers use carbide end mills to machine aluminum fuselage parts at 15,000 RPM. Medical device producers rely on diamond-coated tools for titanium joint replacements needing mirror finishes.

Automotive plants select roughing mills to quickly remove material from engine blocks, then switch to finishing tools for exact tolerances. This staged approach balances speed and precision, cutting production time by 30% compared to single-tool operations.

CNC Turning, Drilling, and Lathe Operations

Modern manufacturing plants achieve rotational perfection through advanced automated systems. These setups spin materials at high speeds while stationary tools shape them into precise cylindrical forms. This method proves indispensable for creating engine pistons, hydraulic valves, and other axially symmetrical components.

Mastering Circular Component Creation

Rotational systems excel where symmetry matters most. A lathe machine grips raw material and rotates it against cutting implements, removing excess stock with micron-level accuracy. Automotive manufacturers use this approach to produce drive shafts that maintain perfect balance at 3,000 RPM.

Integrated drilling operations add functionality without changing setups. Threaded holes for fasteners or fluid channels get created during the same cycle. This seamless process eliminates alignment errors between multiple machines.

| Process | Tolerance | Cycle Time | Surface Finish |

|---|---|---|---|

| Manual Turning | ±0.005″ | 45 min | Ra 125 µin |

| Automated Lathe | ±0.0005″ | 12 min | Ra 32 µin |

Drilling Accuracy in Modern Production

Contemporary systems achieve hole placement accuracy within 0.0001 inches. Medical device makers leverage this precision when creating implant screw threads. Aerospace suppliers drill fuel nozzle orifices that maintain flow rates within 1% variance.

The latest control units synchronize spindle rotation with tool movements. This coordination prevents tool deflection during deep-hole boring operations. “Our defect rate dropped 82% after implementing smart drilling protocols,” reports a Michigan-based auto parts supplier.

These rotational solutions demonstrate how specialized approaches address unique manufacturing challenges. By combining multiple operations in one setup, producers achieve both speed and exactness.

The Precision of CNC Grinding and EDM Processes

Manufacturers face critical decisions when perfecting component surfaces. Two advanced methods dominate high-tolerance finishing: abrasive grinding and electrical discharge techniques. Each approach addresses unique challenges in achieving flawless results.

Abrasive Finishing versus Electrical Discharge Methods

Numerical control systems elevate both processes to unmatched accuracy levels. Grinding employs rotating abrasive wheels to shave microns off hardened steel or ceramics. This creates mirror-like finishes on surgical tools or bearing surfaces. EDM instead uses controlled electrical sparks to erode conductive materials, ideal for intricate molds or aerospace turbine blades.

| Method | Tolerance Range | Material Compatibility | Cycle Time |

|---|---|---|---|

| Abrasive Grinding | ±0.0001″ | Hard metals, ceramics | 15-30 min |

| EDM | ±0.0002″ | Conductive materials | 45-90 min |

Automatic tool changers streamline production by swapping drill bits or electrodes without halting operations. Grinding excels in high-volume scenarios like automotive valve production. EDM shines when cutting complex geometries in superalloys for jet engines. “These methods complement each other—grinding for speed, EDM for impossible angles,” notes a Boeing manufacturing specialist.

Water jet cutting remains popular for thick materials, but lacks the sub-millimeter precision of these electrical and abrasive systems. Advanced numerical control ensures both techniques maintain tolerances tighter than a human hair across thousands of cycles.

Advanced Applications of CNC Plasma Cutting and CNC Routers

Factories worldwide now slice through materials as diverse as aircraft aluminum and artisan wood with equal precision. Thermal and mechanical systems achieve this through innovative approaches tailored to material properties.

Efficiency in Thermal and Router-Based Cutting

Plasma systems use ionized gas reaching 45,000°F to melt through conductive metals. This machine type excels in automotive frame production, cutting steel plates at 500 inches per minute. “You can’t beat plasma for speed on thick metal,” states a Texas-based fabrication shop owner.

Router-based cutting machines transform softer substrates into complex shapes. Carbide bits carve cabinetry joints with 0.002″ accuracy while dust collection systems maintain clean workspaces. Sign makers leverage this technology for detailed lettering in acrylic and hardwood.

Both systems handle materials like composites and alloys through adaptive tooling. Plasma tackles stainless steel exhaust components, while routers shape carbon fiber drone arms. This flexibility allows manufacturers to switch between projects without retooling entire production lines.

Where heat sensitivity matters, waterjet cutting provides cold-cutting alternatives. This process uses high-pressure streams mixed with abrasives, ideal for titanium aircraft parts requiring zero thermal distortion. Medical device producers favor it for creating stainless steel implants with flawless edges.

From architectural metalwork to custom furniture, these machine types demonstrate how modern cutting machines adapt to material challenges. Aerospace suppliers use plasma for lightweight aluminum panels, while router systems craft materials like fiberglass for yacht interiors. Waterjet cutting completes the trio, handling delicate tasks where heat could compromise integrity.

Exploring Control Systems and Multi-Axis CNC Machines

Precision manufacturing enters new dimensions through smart feedback mechanisms and synchronized movement. Modern systems achieve this through advanced control architectures and multi-directional coordination, enabling production of components once deemed too complex for automated methods.

Innovations in Open, Semi-Closed, and Closed Loop Systems

Control architectures determine how equipment responds during operations. Open-loop systems operate without real-time feedback, suitable for basic tasks like cutting plywood sheets. Semi-closed configurations use positional sensors to adjust tool paths mid-process, while closed-loop systems continuously monitor forces and temperatures for micron-level corrections.

Aerospace suppliers report 60% fewer dimensional errors after adopting closed-loop lathe machines for turbine shafts. Medical device makers leverage these systems to maintain ±0.0003″ tolerances on titanium spinal implants.

Multi-Axis Capabilities and Complex Machining

Five-axis CNC routers now create organic shapes in single setups—a task requiring six manual operations previously. This synchronization proves vital for aircraft wing ribs and automotive transmission housings.

- 7-axis systems carve engine blocks with internal coolant channels

- 9-axis configurations mill helicopter rotors while drilling mounting holes

- Laser beam guidance ensures perfect alignment during multi-angle etching

The manufacturing industry sees radical efficiency gains through these advancements. A Michigan automotive plant reduced brake component production from 14 hours to 3.5 using synchronized 5-axis lathe machines. As one engineer states: “We’re machining geometries that blueprints couldn’t accurately describe five years ago.”

CNC Machining in Diverse Industries and Applications

From jet engines to artificial joints, modern production demands tools that adapt to extreme challenges. Advanced manufacturing systems now serve sectors requiring both microscopic precision and industrial-scale output. These solutions bridge the gap between custom prototypes and mass-produced components.

Automotive, Aerospace, and Medical Manufacturing

Critical industries rely on specialized techniques to meet strict standards. Aerospace teams use plasma torch systems to slice titanium fuselage panels while minimizing heat-affected zones. Medical device makers employ end mills thinner than human hair to craft bone screws with 0.0003″ tolerances.

| Industry | Key Technology | Output | Precision Level |

|---|---|---|---|

| Automotive | 5-axis machine works | Transmission gears | ±0.001″ |

| Aerospace | High-velocity plasma torch | Engine mounts | ±0.002″ |

| Medical | Micro-diameter end mills | Dental implants | ±0.0005″ |

Custom Fabrication and Industrial Scale Production

Artisan workshops and factories alike benefit from programmable systems. A California studio recently produced limited-edition aluminum sculptures using waterjet cutting to prevent heat-affected zones. Meanwhile, automotive plants utilize machine works to stamp 5,000 door panels daily with identical specs.

Thermal management remains crucial during high-volume operations. “Controlling torch speed prevents warping in steel components,” explains a fabrication lead at an Ohio plant. This balance enables everything from one-off architectural pieces to aircraft wing mass production.

Material Considerations, Costs, and Efficiency in CNC Machining

Manufacturers face daily choices balancing material performance against budget constraints. The right equipment selection directly impacts product quality and operational profitability. Let’s explore how material properties and system capabilities intersect in modern production environments.

Material Versatility and Surface Finishes

Industrial systems handle everything from aerospace-grade aluminum to carbon-fiber composites. 3-axis systems efficiently process softer materials like ABS plastic for prototyping. Hardened steel requires specialized turning machines with diamond-coated tools to maintain edge integrity.

Surface quality often determines component longevity. CNC grinding achieves Ra 8 µin finishes on medical implants—smoother than glass. Automotive suppliers use this method for transmission gears needing minimal friction. Polished finishes also reduce corrosion risks in marine applications.

Cost-Benefit Analysis and Production Efficiency

Initial investments vary widely between systems. Basic 3-axis units cost $50,000, while multi-axis setups exceed $500,000. However, high-speed turning machines cut per-part costs by 40% in high-volume orders through rapid cycle times.

Energy consumption patterns reveal hidden savings. A Wisconsin plant reduced power bills 18% by switching to servo-driven CNC grinding systems. Tooling expenses drop 30% when using adaptive cutting paths that minimize wear.

| Factor | Plastic Parts | Metal Components |

|---|---|---|

| Cycle Time | 12 minutes | 45 minutes |

| Tooling Cost | $8/unit | $22/unit |

| Finish Quality | Ra 125 µin | Ra 16 µin |

Real-world data shows clear patterns. Electronics manufacturers save $1.2 million annually using modular fixtures on turning machines. Aerospace teams achieve 98% material utilization through optimized nesting software in 3-axis operations.

Future Innovations in CNC Technology and Automation

Factory floors stand poised for transformation as next-gen systems merge artificial intelligence with mechanical precision. These advancements will redefine how components get designed and produced, shrinking the gap between digital concepts and physical results.

Emerging Trends and Automation Solutions

Self-adjusting equipment now learns from each operation. Sensors track tool wear and material hardness, automatically modifying speeds and feeds. Machines in pilot programs achieve 22% faster cycle times through real-time optimization.

Integrated manufacturing ecosystems connect design software directly to production lines. Engineers update part dimensions digitally, and cutting systems adapt within minutes. This seamless flow reduces setup changes from hours to seconds for custom orders.

| Feature | Current Capability | 2025 Projection |

|---|---|---|

| Axis Coordination | 5-axis simultaneous | 9-axis synchronized |

| Error Correction | 0.001″ tolerance | 0.0002″ adaptive |

| Energy Use | 8.5 kW/hour | 4.2 kW/hour |

Advanced control units will predict maintenance needs before failures occur. One aerospace supplier reported 76% fewer unplanned stops after testing predictive algorithms. “Our systems now flag bearing issues three weeks before vibration sensors detect them,” notes their lead engineer.

These innovations promise radical efficiency gains. Early adopters see 40% faster job completion and 18% lower material waste. As smart factories become standard, businesses gain flexibility to handle complex orders without sacrificing speed or precision.

Conclusion

Modern production landscapes thrive on exactness and adaptability. Computer-guided systems have proven indispensable for creating components that meet strict tolerances while handling diverse materials like aerospace alloys and medical-grade plastics. From multi-axis sculpting to thermal slicing, each method serves unique needs while maintaining consistent quality.

Choosing the proper tool directly impacts project success. Milling achieves complex contours, turning produces symmetrical parts, and plasma systems slice thick metals efficiently. As highlighted in this comprehensive guide, matching equipment capabilities to design requirements ensures optimal results across industries.

Emerging technologies continue pushing boundaries. Smart sensors now adjust operations in real time, while AI-driven systems predict maintenance needs. These advancements let manufacturers tackle intricate designs previously deemed unworkable.

Businesses embracing these innovations position themselves at the forefront of their fields. By leveraging precision systems and evolving techniques, companies unlock new possibilities in speed, accuracy, and customization. The future belongs to those who harness these tools to transform digital visions into tangible excellence.

FAQ

What distinguishes milling from turning in precision manufacturing?

Milling uses rotating cutting tools like end mills to shape stationary workpieces, ideal for complex 3D parts. Turning rotates materials against fixed tools, perfect for cylindrical components such as shafts or valves.

How do plasma cutting systems differ from laser or waterjet methods?

A: Plasma cutting uses ionized gas for conductive metals, creating minimal heat-affected zones. Laser systems focus light beams for intricate cuts in plastics or thin metals, while waterjet employs abrasives for thick materials without thermal distortion.

Which industries benefit most from multi-axis systems like Haas or Mazak?

Aerospace relies on 5-axis machines for turbine blades, while automotive uses them for engine blocks. Medical sectors apply CNC grinding for surgical tools, and electronics depend on routers for circuit board prototyping.

What materials work best with electrical discharge machining (EDM)?

EDM excels with hardened steels, titanium, and carbides. It’s preferred for molds or aerospace parts requiring sharp edges and fine details without mechanical stress, unlike traditional cutting tools.

How do open-loop and closed-loop control systems affect accuracy?

Open-loop systems, like older CNC lathes, lack real-time feedback. Closed-loop systems from brands like Fanuc or Siemens use encoders to correct errors instantly, ensuring micron-level precision in aerospace components.

Why choose waterjet cutting over thermal methods for certain projects?

Waterjet avoids heat distortion, making it ideal for sensitive materials like composites or tempered glass. It’s slower than plasma torches but ensures clean edges in food-grade or architectural applications.

What surface finishes can be achieved with abrasive finishing techniques?

Processes like CNC grinding deliver Ra values below 0.4 µm for medical implants. Vibratory tumbling or electrochemical polishing enhances corrosion resistance in marine or automotive components.

How do costs vary between 3-axis and 5-axis machines for prototyping?

While 3-axis mills like Tormach are cost-effective for simple parts, 5-axis systems reduce setups for complex geometries. High-volume production often justifies the upfront investment in multi-axis setups.