HDPE vs LDPE: Which Plastic for Injection Molding? [2025 Interactive Guide]

Published on by MoldMinds Staff | 14 min read

Choosing between HDPE and LDPE for your injection molding project? You're not alone. These two polyethylene variants account for over 50% of all plastic production globally, yet picking the wrong one can cost you thousands in redesigns, failed parts, and production delays.

This comprehensive guide gives you everything you need: an interactive material selector wizard, real-time property comparisons, cost calculators, processing parameters, and expert insights from 15+ years of injection molding experience. By the end, you'll know exactly which material suits your project—and why.

🎯 Smart Material Selector Wizard

Answer 5 quick questions to get your personalized HDPE vs LDPE recommendation

What type of product are you making?

What's your primary requirement?

What temperature range will the part experience?

What's your expected production volume?

How important is material cost vs. performance?

We Recommend: HDPE

Based on your requirements, HDPE is the optimal choice for your application.

📊 Material Specifications for Your Project

Recommended: HDPE

Alternative: LDPE

🎯 Why This Material Works for You

⚙️ Injection Molding Parameters

Quick Comparison: HDPE vs LDPE

HDPE (High-Density)

- Density: 0.941-0.965 g/cm³

- Strength: 22-35 MPa

- Feel: Rigid, hard

- Temperature: Up to 120°C

- Best For: Bottles, containers, pipes

- Cost: $1.20-1.40/lb

- Recyclable: #2 (widely accepted)

LDPE (Low-Density)

- Density: 0.910-0.940 g/cm³

- Strength: 8-16 MPa

- Feel: Flexible, soft

- Temperature: Up to 80°C

- Best For: Films, bags, squeeze bottles

- Cost: $1.10-1.30/lb

- Recyclable: #4 (limited acceptance)

Interactive Property Comparison

See how HDPE (blue) compares to LDPE (orange) across key properties:

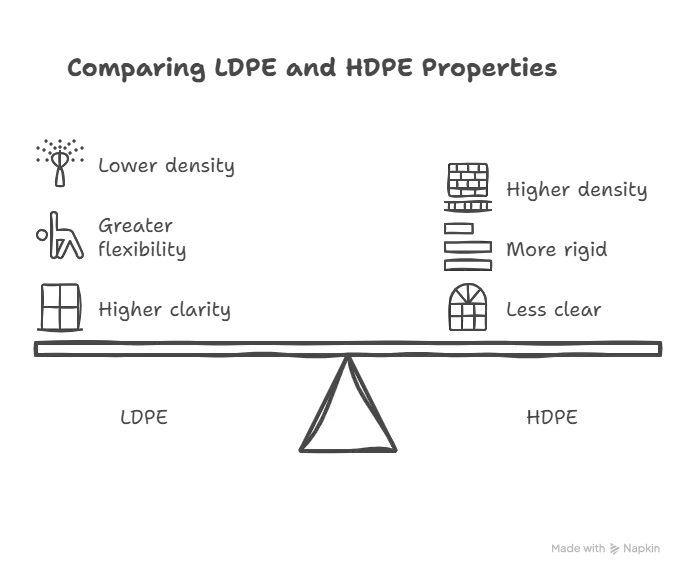

✅ HDPE is 2-3x stronger

✅ LDPE wins for flexibility

✅ HDPE handles higher temperatures

✅ HDPE more resistant to acids/bases

✅ LDPE offers better clarity

Understanding High-Density Polyethylene (HDPE)

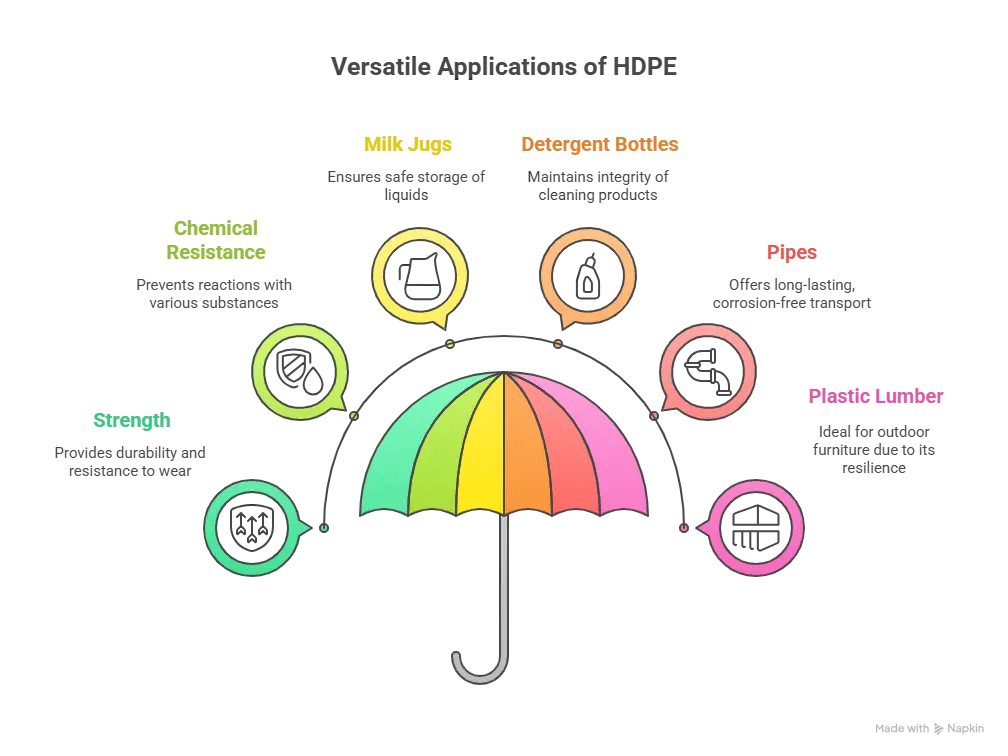

High-Density Polyethylene is everywhere—from milk jugs to industrial pipes. But what makes it so versatile? It's all about that molecular structure. HDPE features predominantly linear chains with minimal branching, like neatly stacked boxes. This tight packing creates superior strength, rigidity, and chemical resistance.

Key Properties of HDPE

- High Strength and Rigidity: Tensile strength of 22-35 MPa handles stress without deforming

- Chemical Resistance: Excellent resistance to acids, bases, and most solvents

- Low Moisture Absorption: Perfect for outdoor applications and wet environments

- Impact Resistance: Withstands impacts without cracking, even at low temperatures

- Recyclability: Plastic #2, widely accepted in curbside recycling programs

- High Strength-to-Weight Ratio: Critical factor in plastic part design

💡 Design Tip from 15 Years of Tooling

When designing HDPE parts, account for 1.5-3.0% shrinkage. Its high crystallinity (60-80%) means more dimensional change during cooling. Our moldflow analysis services can predict this precisely, preventing costly mold corrections.

| Property | Value |

|---|---|

| Density | 0.941 to 0.965 g/cm³ |

| Tensile Strength | 22 to 35 MPa |

| Melting Point | 120 to 140 °C |

| Chemical Resistance | Excellent to most acids and bases |

| Melt Temperature | 200-280°C |

| Shrinkage Rate | 1.5-3.0% |

Exploring Low-Density Polyethylene (LDPE)

Low-Density Polyethylene is the flexible counterpart to HDPE. Its highly branched molecular structure—imagine a tangled ball of yarn—prevents tight packing, resulting in lower density (0.910-0.940 g/cm³) and that characteristic soft, flexible feel. This structure gives LDPE unique properties perfect for applications requiring flexibility and transparency.

Manufacturing Process of LDPE

LDPE manufacturing uses high-pressure free-radical polymerization—ethylene gas is subjected to extreme pressures (up to 50,000 psi) and high temperatures. This process creates those characteristic branched chains that define LDPE's properties. After polymerization, the polymer is cooled and pelletized for injection molding or extrusion.

Key Properties of LDPE

- Superior Flexibility: Highly flexible, ideal for applications requiring bending or stretching

- Excellent Clarity: Good transparency allows easy visibility of contents

- Chemical Resistance: Good resistance to many chemicals, though less than HDPE

- Water Resistance: Highly resistant to moisture, perfect for barrier applications

- Low-Temperature Performance: Remains flexible below 0°C when HDPE becomes brittle

- Recyclability: Plastic #4, though less commonly accepted than HDPE

⚠️ Common LDPE Design Mistake

LDPE's flexibility is both a feature and a challenge. Don't use it for structural parts expecting HDPE-like rigidity. We've seen projects fail because engineers chose LDPE for cost savings, then needed expensive reinforcement ribs later. Material selection matters more than mold cost—get it right the first time with our consulting services.

💰 Material Cost Calculator

Calculate estimated material costs for your project

📊 Cost Analysis

Processing Parameters: The Technical Details That Matter

Choosing the right material is step one. Getting the processing parameters right is step two—and often where projects succeed or fail. Here's what your injection molding team needs to know:

| Parameter | HDPE | LDPE | Impact on Production |

|---|---|---|---|

| Melt Temperature | 200-280°C | 160-260°C | HDPE requires more heating energy; longer startup |

| Mold Temperature | 20-60°C | 20-40°C | HDPE benefits from warmer molds for better finish |

| Injection Pressure | 50-150 MPa | 40-100 MPa | HDPE's viscosity requires more pressure |

| Cooling Time | 15-60 seconds | 10-45 seconds | LDPE cools faster = shorter cycle times |

| Shrinkage | 1.5-3.0% | 1.5-5.0% | Both require shrinkage compensation in mold design |

🎯 Pro Tip: Cycle Time Optimization

LDPE's lower melting point and faster cooling can reduce cycle times by 10-20% compared to HDPE for similar part geometries. This translates to 10-20% more parts per day. However, don't let cycle time alone drive material selection—a flexible LDPE part might require expensive secondary operations that eliminate the time savings. Our project management services help you optimize for total cost, not just cycle time.

Applications and Uses of HDPE and LDPE

Common Uses of HDPE (The Rigid Workhorse)

- Milk jugs and detergent bottles

- Pipes for water and gas lines

- Plastic lumber for outdoor furniture

- Toys and playground equipment

- Chemical and industrial containers

- Automotive fuel tanks

- Food storage containers

Common Uses of LDPE (The Flexible Friend)

- Plastic bags (grocery, trash, dry cleaning)

- Film wrap (food packaging, shrink wrap)

- Squeeze bottles (honey, mustard, lotions)

- Flexible lids for containers

- Agricultural films

- Wire and cable insulation

- Greenhouse films

Industry-Specific Applications

In large-scale infrastructure, HDPE is preferred for water and gas distribution pipes due to its durability, long lifespan, and chemical resistance. In agriculture, LDPE is commonly used for greenhouse films. In packaging, both are used, but for different purposes—HDPE for rigid containers, LDPE for flexible wraps. Our injection molding consulting often helps clients determine which material, and which process, is best for their product.

Environmental Impact and Recyclability

HDPE Recycling (#2)

- Recycling Rate: ~30% in US

- Accepted: Most curbside programs

- Process: Sorted → Shredded → Cleaned → Melted → Pelletized

- Applications: Recycled into bottles, containers, plastic lumber

- Quality Loss: Minimal degradation through 2-3 cycles

LDPE Recycling (#4)

- Recycling Rate: ~5% in US

- Accepted: Limited curbside; store drop-off bins

- Challenge: Film/bags clog sorting machinery

- Applications: Garbage bags, floor tiles, furniture

- Quality Loss: More degradation; typically downcycled

🌍 Sustainability Consideration

While both materials are theoretically recyclable, HDPE's infrastructure advantage means more of it actually gets recycled. If environmental impact is a priority, HDPE offers better end-of-life management. However, the best choice is still the one that prevents product failure—a failed LDPE part that gets replaced has worse environmental impact than the right HDPE part used once. For more information, check out the EPA's data on plastics.

Choosing the Right Polyethylene for Your Needs

Decision Matrix: HDPE or LDPE?

Choose HDPE if you need:

- High Strength & Rigidity

- Excellent Chemical Resistance

- Higher Temperature Resistance (120°C)

- Good Impact Resistance

- An Opaque Material

- Better Recyclability

- Structural Applications

Choose LDPE if you need:

- High Flexibility & Softness

- Good Transparency/Clarity

- Good Moisture Barrier

- Ease of Squeezing

- Lower Cost (often)

- Low-Temperature Flexibility

- Film Applications

For more in-depth help, check out our free resources or contact us for a consultation.

Frequently Asked Questions

The fundamental difference is molecular structure: HDPE has linear chains that pack tightly (high density, high strength), while LDPE has branched chains that pack loosely (low density, high flexibility). This structural difference drives all other property differences—strength, temperature resistance, flexibility, and transparency.

Not recommended unless your application specifically needs flexibility. While LDPE costs $0.10-0.20/lb less, using it for applications requiring rigidity will lead to part failure, customer complaints, and expensive redesigns that far exceed the material savings. Choose based on performance requirements first, then optimize costs within that constraint.

HDPE is generally better for outdoor use due to superior UV resistance, weatherability, and dimensional stability across temperature fluctuations. It's widely used for outdoor furniture, playground equipment, and signage. LDPE can be used outdoors but typically requires UV stabilizers and works best for flexible applications like agricultural films or pond liners.

HDPE requires higher melt temperatures (200-280°C vs 160-260°C), higher injection pressures (50-150 MPa vs 40-100 MPa), and typically longer cooling times. LDPE flows more easily and cools faster, often reducing cycle times by 10-20%. Both require mold shrinkage compensation (1.5-3% for HDPE, 1.5-5% for LDPE).

Yes, both are FDA-approved for food contact when properly formulated. HDPE is commonly used for milk jugs, juice bottles, and food storage containers. LDPE is used for squeezable bottles, plastic wrap, and flexible food packaging. Always verify that your specific resin grade has FDA approval for your intended use.

HDPE (#2) is significantly more recyclable in practice, with ~30% recycling rates and acceptance in most curbside programs. LDPE (#4) has only ~5% recycling rates because film and bag forms clog sorting machinery. Many grocery stores offer LDPE film drop-off bins, but infrastructure is limited compared to HDPE.

They can be blended, but properties will be intermediate between the two and often unpredictable. Some manufacturers create MDPE (Medium-Density Polyethylene) by blending, targeting specific property ranges. However, for most injection molding applications, it's better to choose the pure resin that best fits your requirements rather than attempting to blend.

It depends on temperature: HDPE has better impact resistance at room temperature and above due to its higher strength. However, LDPE performs better at low temperatures (below 0°C) because it remains flexible while HDPE becomes brittle. For freezer applications or cold storage, LDPE is often the better choice despite its lower overall strength.

Need Help Choosing the Right Material for Your Project?

Material selection is just the beginning. Successful injection molding requires expert mold design, precise parameter optimization, and experienced project management.

Our Services:

- ✅ Material Selection Consulting - Get expert guidance on HDPE vs LDPE for your specific application

- ✅ Moldflow Analysis - Predict shrinkage, warp, and fill patterns before cutting steel

- ✅ Plastic Part Design - DFM optimization to prevent costly redesigns

- ✅ Tooling Project Management - From quote to first article, we manage it all

15 years injection molding expertise. Managed 200+ tooling projects. Saved clients $2M+ through optimized material selection and mold design. Let's make your project succeed.