Offshore Tooling for Injection Molding:

Complete Cost Savings Guide

The definitive playbook for slashing tooling costs by 40-60% without compromising quality. Real strategies, proven frameworks, and an interactive ROI calculator from the experts at MoldMinds.

Every dollar you overspend on tooling is a dollar that never makes it to your bottom line. In an industry where margins are measured in fractions of a cent per part, offshore tooling for injection molding has become the single most impactful cost reduction strategy available to competitive manufacturers.

But here's the uncomfortable truth most won't tell you: the difference between massive savings and catastrophic failure comes down to execution. This guide gives you the complete framework for capturing 40-60% cost reductions—the same strategies MoldMinds uses to deliver predictable results for our clients.

What This Guide Delivers

A complete cost savings roadmap: realistic savings calculations, hidden cost factors most overlook, decision frameworks for when offshore makes sense, and an interactive ROI calculator to model your specific situation. No fluff—just actionable intelligence.

The Real Economics of Offshore Tooling for Injection Molding

Let's cut through the noise. Offshore tooling—primarily from China, but increasingly from Vietnam and India—delivers genuine cost advantages that compound across your entire production lifecycle. Understanding the complete cost picture is essential for making informed sourcing decisions.

The sticker price tells only part of the story. World-class offshore partners offer access to massive manufacturing ecosystems, deep specialization in complex mold configurations, and production capacities that most domestic shops simply cannot match—all at significantly lower price points.

Breaking Down the True Cost Savings

Sophisticated buyers know that headline savings require careful analysis. The true cost calculation must account for shipping and logistics (typically 3-5% of tool value), import duties and tariffs (currently 7.5-25% depending on classification), quality validation and T1/T2 sampling, project management overhead, and timeline risk factors.

Even with every cost factor included, offshore tooling for injection molding consistently delivers 40-60% total cost reduction compared to domestic alternatives. On a $100,000 domestic quote, that's $40,000-$60,000 back in your pocket—money that drops straight to the bottom line or funds additional product development. Use our calculator below to model your specific savings.

5 Key Factors That Maximize Your Cost Savings

High-Cavity Tools

Multi-cavity molds see the biggest savings—offshore costs scale more efficiently as complexity increases.

Complex Geometries

Slides, lifters, and actions that command premium domestic pricing are standard offshore capabilities at fraction of the cost.

Timeline Flexibility

Projects with 10-14 week timelines unlock the best pricing. Rush fees erode savings significantly.

Volume Production

High annual volumes amplify per-part savings—tooling cost reductions compound across every unit produced.

When Domestic Tooling Still Wins

Cost savings aren't everything. Domestic tooling remains the smart choice for extreme time sensitivity (under 6-week requirements), highly proprietary designs requiring maximum IP protection, tools requiring frequent engineering changes during development, and medical or aerospace applications with stringent documentation requirements. Knowing when not to go offshore is just as important as knowing when to do it.

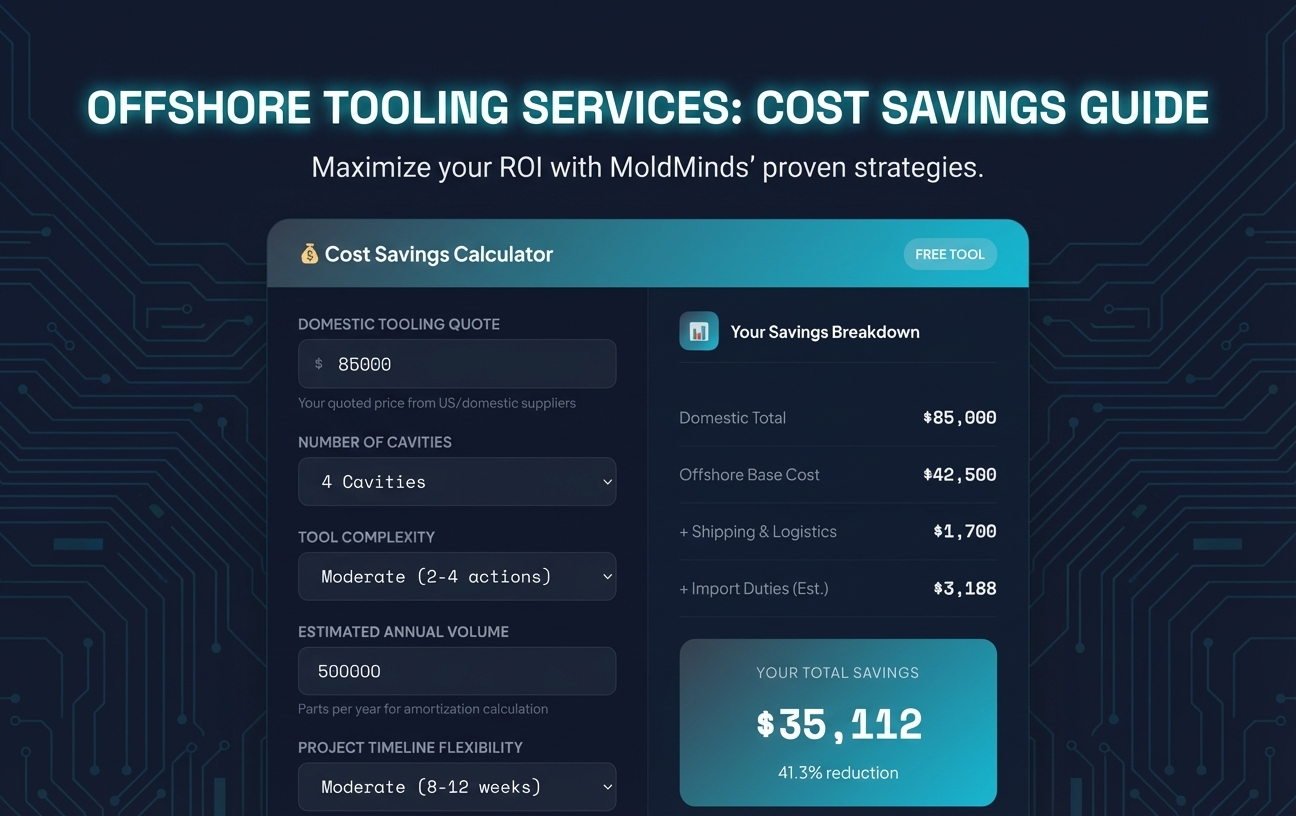

Calculate Your Cost Savings

See exactly how much you could save with offshore tooling for injection molding. Input your project specs and get an instant cost comparison with detailed breakdown.

Your Savings Breakdown

How MoldMinds Maximizes Your Savings

Here's something the calculator can't show you: most offshore tooling failures aren't caused by the suppliers. They're caused by poor specifications, communication breakdowns, and the absence of experienced intermediaries who understand both Western quality expectations and Asian manufacturing realities.

These failures don't just cost money—they cost time, destroy schedules, and erode the very savings you were chasing. MoldMinds exists to ensure you capture the full cost advantage of offshore tooling for injection molding without the risks that sink most DIY efforts.

Our Cost-Optimized Process

Phase 1: Cost Analysis

We analyze your part geometry, production volumes, and timeline to identify maximum savings potential and optimal supplier matching.

Phase 2: DFM Cost Optimization

Our engineers review designs for manufacturability, identifying opportunities to reduce tool complexity and cost before RFQ submission.

Phase 3: Competitive Bidding

We leverage our vetted supplier network to secure competitive pricing while ensuring quality standards—maximizing your cost advantage.

Phase 4: Quality Assurance

Rigorous T1/T2 protocols and dimensional verification prevent costly rework and ensure tools meet spec on first delivery.

Phase 5: Logistics Optimization

Coordinated shipping and customs clearance to minimize landed costs and get your tools into production faster.

Protecting Your Savings: Common Pitfalls to Avoid

Hidden Quality Costs

The myth that offshore tools are inherently lower quality is outdated. Today's leading Chinese toolmakers utilize the same equipment—Makino, Sodick, GF Machining—found in premium domestic shops. The real risk is unclear specifications that lead to costly rework. Detailed DFM upfront eliminates this savings killer.

Communication Delays

Time zone gaps and language barriers create friction that extends timelines—and extended timelines erode savings. Our bilingual team maintains daily communication during critical phases, translating not just words but technical intent and quality expectations.

IP Protection Costs

Some projects require domestic tooling regardless of cost. For most applications, a layered approach—careful supplier selection, contractual protections, strategic component distribution—provides adequate IP security while preserving the offshore cost advantage.

Start Capturing Your Cost Savings

Offshore tooling for injection molding delivers real, measurable cost reductions for manufacturers who execute correctly. The calculator above gives you a starting point—but every project has nuances that impact the final numbers.

Whether you're sourcing your first offshore tool or optimizing an existing supply chain, MoldMinds provides the expertise to maximize your savings while eliminating the risks that derail DIY efforts.

Ready to Cut Your Tooling Costs?

Get a detailed cost analysis for your specific project. Our team will review your requirements and show you exactly how much you could save with offshore tooling—no obligation.

MoldMinds Editorial Team

Helping US manufacturers capture 40-60% tooling cost savings through strategic offshore partnerships. Deep expertise in injection mold engineering combined with established Asian supplier relationships.