How to Source Injection Molds from China: Complete 2025 Guide

Published on | By MoldMinds Staff | 15 min read

Why Source Injection Molds from China?

The Compelling Economics

| Mold Type | US Cost | China Cost | Savings | Payback (at 10K parts) |

|---|---|---|---|---|

| Simple 2-Cavity | $18,000 | $8,000 | $10,000 (56%) | Immediate |

| Standard 4-Cavity | $35,000 | $15,000 | $20,000 (57%) | Immediate |

| Complex 8-Cavity Hot Runner | $95,000 | $45,000 | $50,000 (53%) | Immediate |

When China Sourcing Makes Sense

- Budget-Conscious Projects: When tooling cost is a significant portion of your budget (>20% of total project cost)

- Moderate to High Volume: Planning to produce 10,000+ parts where mold cost per part matters

- Standard Complexity: Not requiring extreme tolerances (±0.001") or exotic materials

- Flexible Timelines: Can accommodate 8-12 week lead times plus shipping

- Willing to Manage: Have time/resources to properly manage the offshore relationship

When to Consider Domestic Manufacturing

- Extreme Precision: Medical implantables, aerospace components requiring ±0.0005" tolerances

- Rush Timelines: Need mold in less than 6 weeks

- Very Low Volume: Under 5,000 parts lifetime (cost per part won't justify savings)

- Frequent Changes: Expect multiple design iterations requiring quick revisions

- Highly Confidential IP: Classified, defense, or ultra-sensitive intellectual property

Our injection molding consulting services include manufacturer selection guidance, cost-benefit analysis, and risk assessment to help you make the right sourcing decision for your specific project.

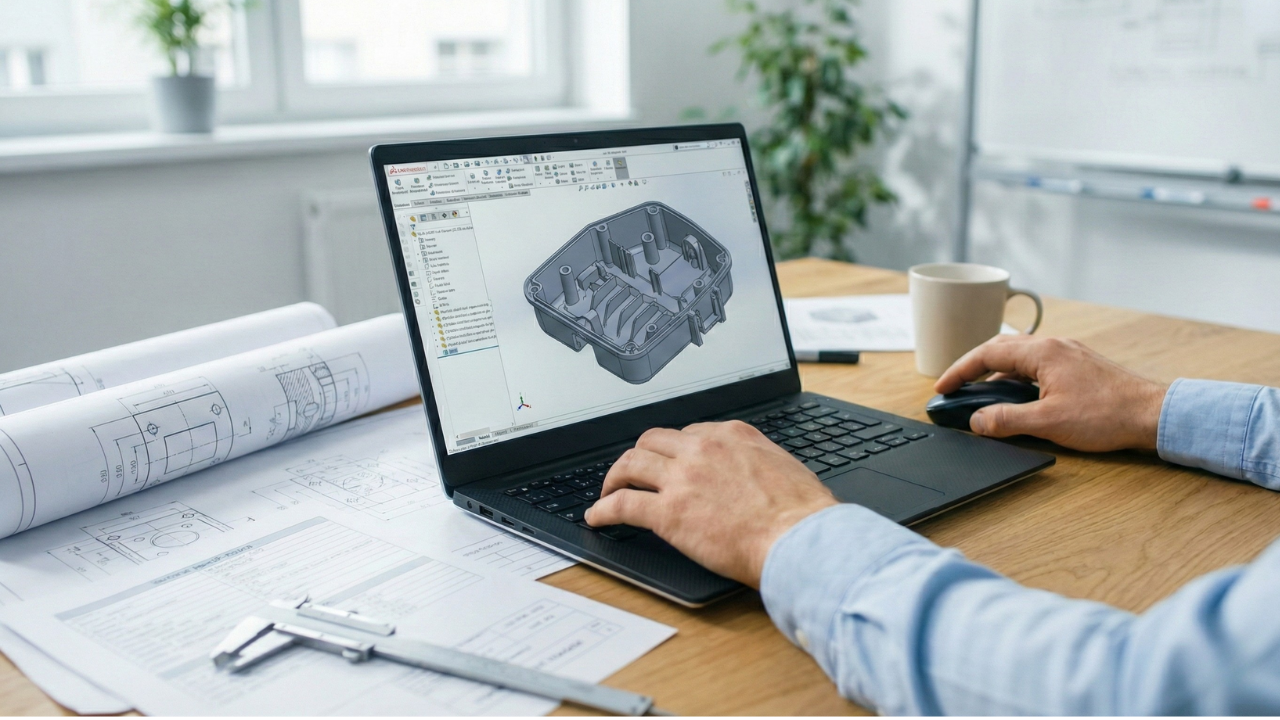

Step 1: Prepare Your RFQ Package to Source Injection Molds from China

Essential RFQ Components

- 3D CAD Files - STEP or IGES format (universal), NOT native files unless requested

- 2D Technical Drawings - PDF format with critical dimensions, tolerances (±0.001"), GD&T callouts, and surface finish requirements (Ra values)

- Material Specification - Exact resin grade and supplier (e.g., "Sabic PC/ABS C2950" not just "PC/ABS")

- Production Volume Forecast - Annual volume (helps them recommend mold life/steel grades)

- Quality Requirements - Inspection standards, documentation needs, certifications required

- Timeline Requirements - When you need first articles and production start date

- Special Requirements - Colors, textures (MT-11010, SPI-A2, etc.), insert molding, overmolding

- Quantity of Molds - Number of identical molds needed (affects pricing)

- Shipping Destination - Affects shipping quotes and import considerations

RFQ Best Practices

Before sending your RFQ, have a DFM review done. Identifying and fixing design issues BEFORE quoting saves weeks of back-and-forth and prevents surprises during production. Our plastic part design services include comprehensive DFM analysis.

- Be Specific About Tolerances: Don't say "tight tolerances"—specify exactly which dimensions need ±0.001" vs. ±0.005"

- Include Part Weight: If known, include expected part weight (helps them validate cavity count and machine size)

- Specify Inspection Requirements: First article inspection (FAI), ongoing SPC, dimensional reports—spell it out

- Clarify What's Included: Ask explicitly what's included in the quote: samples, revisions, shipping, etc.

- Set Response Deadline: Give manufacturers 5-7 business days to respond (too short = rushed quotes; too long = they forget)

Sample RFQ Email Template

Subject: RFQ: [Part Name] Injection Mold - [Your Company]

Dear [Manufacturer Name],

We are seeking quotes for an injection mold for our [product description]. Please find attached:

- 3D CAD file (STEP format)

- 2D technical drawings with tolerances

- Material specification

Project Details:

- Part: [Name/Number]

- Material: [Exact grade, e.g., "Sabic PC/ABS C2950"]

- Annual Volume: [Number] parts

- Cavities: [Preferred number, or ask for recommendation]

- Surface Finish: [Specify texture/polish requirements]

- Required Certifications: [ISO 9001, IATF 16949, etc.]

Please include in your quote:

- Mold cost breakdown (base, cavities, hot runner if applicable)

- Lead time from PO to first samples

- Number of sample shots included

- Revision policy (how many rounds included?)

- Payment terms

- Shipping cost to [destination]

- Warranty/tool life guarantee

Please respond by [Date - 7 days from now].

Thank you,

[Your Name]

[Company]

[Contact Info]

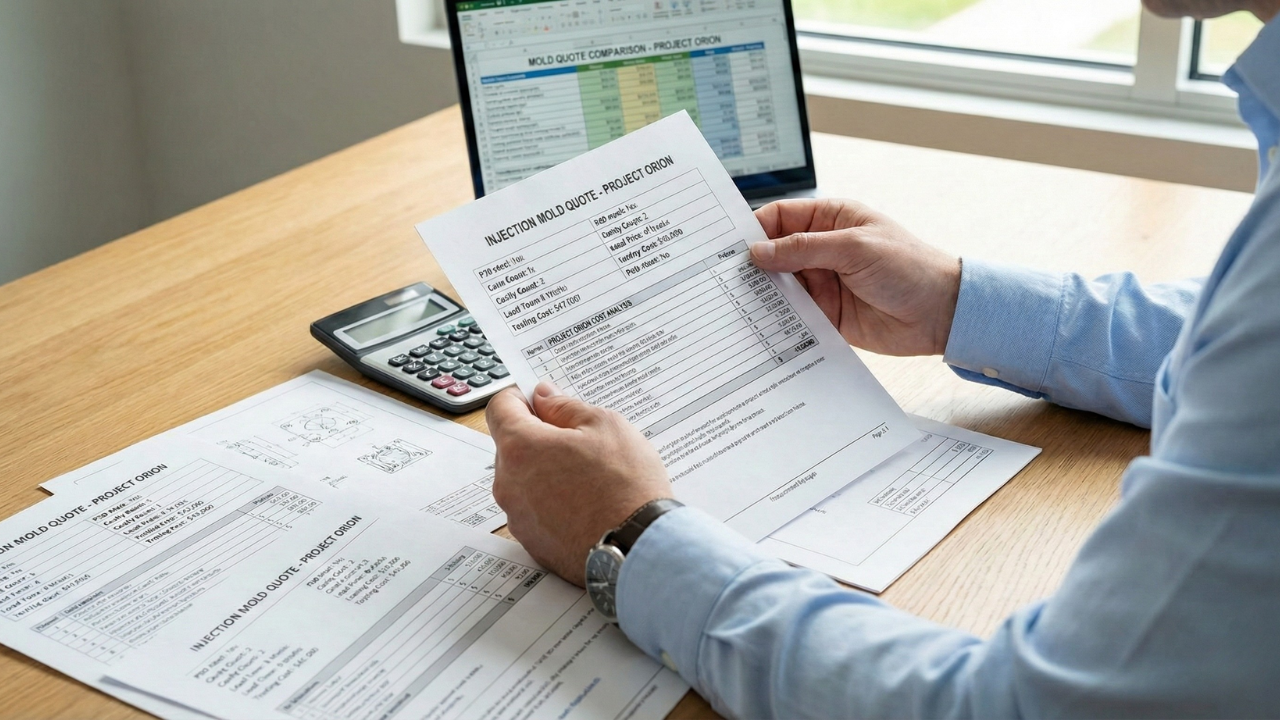

Step 2: Request and Evaluate Quotes

How to Find Manufacturers

- Start with Our Top 10 List: Review our verified manufacturers guide for pre-vetted options

- Alibaba: Use verified suppliers with Trade Assurance, 5+ years on platform, and good reviews

- Industry Trade Shows: NPE, Chinaplas, PLASTIMAGEN for in-person connections

- Referrals: Ask colleagues in your industry for recommendations

- Google Search: "[your industry] injection mold manufacturer China" + check their website quality

Evaluating Quotes: What to Look For

| Factor | What to Check | Red Flags |

|---|---|---|

| Price | Within 20% of median quote | 40%+ below others with no explanation |

| Detail Level | Itemized breakdown (base, cavities, hot runner) | Single line item "Mold - $XX,XXX" |

| Lead Time | Realistic 6-10 weeks for standard molds | Promises 3 weeks for complex mold |

| What's Included | Clearly states samples, revisions, shipping | Vague or missing information |

| Steel Grade | Specifies P20, H13, S136, etc. | Just says "good quality steel" |

| Payment Terms | 40-50% deposit, balance on milestones | Requires 100% upfront |

| Warranty | 300K-500K shot guarantee specified | No warranty mentioned |

Critical Questions to Ask

- What steel grade is included for cavity/core? (P20 standard, H13 for high-volume, S136 for corrosion resistance)

- How many sample shots are included in the price?

- How many rounds of revisions are free? What's the cost for additional revisions?

- Is hot runner system included? (If applicable - adds $3,000-$15,000)

- What surface finish is included? (Standard, texture, high-polish?)

- Is mold base HASCO, DME, LKM, or custom?

- What is your tool life guarantee? (Minimum 300,000 shots)

- What documentation will you provide? (Mold layout drawings, steel certificates, dimensional reports)

- Can we have a third-party inspector visit during production?

- What is your revision turnaround time?

- Quote is 40%+ lower than others with identical specs (probably cutting corners)

- Refuses to provide customer references

- No factory photos or reluctance to do virtual tour

- Demands 100% payment upfront

- Poor English with no offer of translator (communication will be nightmare)

- Cannot or will not specify steel grades

- Provides quote immediately without asking clarifying questions (didn't review your files)

Step 3: Conduct Due Diligence When Sourcing Injection Molds from China

Verification Checklist

- Verify Certifications:

- Request certificate copies (ISO 9001, IATF 16949, ISO 13485)

- Verify authenticity on certifying body's website

- Check expiration dates

- Check References:

- Request 3-5 customer references (preferably in your country/industry)

- Actually call them (don't just email)

- Ask about quality, communication, on-time delivery, responsiveness to issues

- Virtual Factory Tour:

- Schedule 30-60 minute video call walking through facility

- See their CNC machines, EDM equipment, inspection tools

- Meet key personnel (project manager, quality manager)

- Assess organization and cleanliness

- Verify Business License:

- Request copy of Chinese business license

- Verify on Chinese government business database if possible

- Check company age (prefer 5+ years in business)

- Financial Stability Check:

- If publicly listed, review financial statements

- Check Alibaba verification level if applicable

- Ask about number of employees (stability indicator)

Questions to Ask References

- How long have you worked with this manufacturer?

- How many molds have you sourced from them?

- What was the on-time delivery rate?

- How did they handle issues or revisions?

- How was communication (response time, English proficiency)?

- Did the final mold meet specifications?

- How was the mold's durability/performance in production?

- Would you use them again? Why or why not?

- Any surprises or hidden costs?

If something feels off during due diligence—vague answers, reluctance to provide information, inconsistent stories—trust that instinct. There are hundreds of manufacturers; move on to the next candidate. The best manufacturers are transparent and eager to prove their capabilities.

Step 4: Negotiate Contract Terms

Essential Contract Elements

- Detailed Scope: Number of cavities, steel grades, mold base type, surface finishes, special features

- Payment Schedule: Typically 40% deposit, 30% at first article approval, 30% before shipment

- Timeline with Milestones: Design approval, steel ordered, roughing complete, EDM/polishing done, sampling, shipment

- Revision Policy: Number of free revision rounds (typically 1-2), cost for additional revisions, turnaround time

- Quality Standards: Dimensional tolerances, surface finish specs, inspection protocols

- Deliverables: Mold layout drawings, steel certificates, dimensional reports, sample parts

- IP Protection: NDA, ownership of tooling and designs, no reverse engineering clause

- Inspection Rights: Your right to conduct or hire third-party inspections

- Late Delivery Terms: Penalties or discounts for missed deadlines (e.g., 5% per week late)

- Warranty: Tool life guarantee (typically 300K-500K shots), coverage terms, repair policy

- Shipping Terms: Who arranges shipping, who pays, insurance, risk transfer point (Incoterms)

- Dispute Resolution: Arbitration location/method, governing law

Payment Terms Negotiation

| Payment Structure | Risk Level | When to Use |

|---|---|---|

| 40/30/30 Split (40% deposit, 30% at FAI, 30% before ship) | Balanced | Standard for most projects $10K-$50K |

| 30/30/40 Split (30% deposit, 30% at FAI, 40% before ship) | Lower Buyer Risk | First-time manufacturer relationship |

| Letter of Credit (Bank-guaranteed payment) | Lowest Risk | Large orders over $100K, unfamiliar manufacturers |

| Escrow Service (Third-party holds funds) | Low Risk | First-time relationship, moderate orders |

| 50/50 Split (50% deposit, 50% before ship) | Higher Buyer Risk | Only with established, trusted manufacturers |

- 100% payment upfront (massive red flag!)

- Full payment before seeing first article samples

- Payment via Western Union or MoneyGram (untraceable)

- Contracts without specific deliverables or milestones

- Vague quality standards ("good quality" doesn't mean anything legally)

IP Protection Strategies

- Use Comprehensive NDAs: Have manufacturer sign before sharing any designs

- Register IP in China: For critical designs, file Chinese patents/trademarks

- Split Production: For highly sensitive products, consider splitting work across 2-3 manufacturers

- Clear Ownership Clause: Contract must state YOU own the tooling and all designs

- No Third-Party Clause: Manufacturer cannot use your designs for other customers

- Destruction Upon Completion: Require deletion of CAD files after project completion (if desired)

Continue Reading: Steps 5-8 & Common Mistakes

The remaining steps cover design review, production monitoring, sample approval, shipping logistics, and the most common sourcing mistakes to avoid.

Article continues below...

Step 5: Design Review & Approval

Key Review Points: Gate locations, parting line placement, ejector pin positions, cooling layout, slide/lifter mechanisms, venting strategy. Always get engineering input—a $1,000 review can prevent $10,000 in revisions.

Step 6: Monitor Production

Documentation to Request: Steel certificates, progress photos, dimensional measurements, cooling system testing. Good manufacturers provide this proactively.

Step 7: Sample Approval

- Surface finish meets specifications (check texture, polish, gate vestige)

- Critical dimensions within tolerance (use calibrated measuring tools)

- No flash on parting lines

- Snap fits, living hinges, threads function properly

- Color consistency (if colored resin used)

- Process parameters documented (temperature, pressure, cooling time)

- Material certification provided

For orders over $20,000, strongly consider hiring third-party inspection (SGS, Bureau Veritas, QIMA) for $500-$1,500. It's cheap insurance.

Step 8: Shipping & Delivery

| Shipping Method | Transit Time | Cost (Small Mold) | Best For |

|---|---|---|---|

| Air Freight | 5-7 days | $800-$1,500 | Urgent timelines, high-value molds |

| Sea Freight (LCL) | 30-45 days | $500-$800 | Standard projects, budget-conscious |

| Sea Freight (FCL) | 30-45 days | $3,000-$5,000 (full container) | Multiple large molds |

Top 10 Sourcing Mistakes (And How to Avoid Them)

The Problem: The cheapest quote is often cheap for a reason—inferior steel, shortcuts in process, inexperienced staff.

The Solution: Evaluate total value including communication quality, certifications, references, and timeline reliability. A $5,000 savings isn't worth a $20,000 disaster.

The Problem: "We need tight tolerances" means nothing. Manufacturer assumes ±0.005", you expected ±0.001".

The Solution: Specify exact tolerances on critical dimensions. Use GD&T callouts. Define surface finish requirements numerically (Ra 0.8, SPI-A2, etc.).

The Problem: Design issues discovered after steel is cut = expensive revisions and delays.

The Solution: Invest in proper DFM analysis and moldflow simulation before quoting. $2,000 upfront saves $15,000 later.

The Problem: "But they said..." doesn't hold up when things go wrong. Verbal agreements are worthless.

The Solution: Always have a comprehensive written contract. If manufacturer resists formal paperwork, that's a red flag—find someone else.

The Problem: Assuming "no news is good news" leads to surprises at delivery.

The Solution: Establish weekly update schedule. Require photo documentation at milestones. Schedule video calls for complex discussions. Use project management tools (Trello, Asana) for transparency.

- #6 - No IP Protection: Use NDAs and contracts with clear ownership clauses. For critical IP, register patents in China.

- #7 - Unrealistic Timelines: "We need it in 4 weeks" for a complex 8-cavity mold is fantasy. Standard is 6-10 weeks; complex is 10-14 weeks.

- #8 - Ignoring Cultural Differences: Direct confrontation is uncomfortable in Chinese culture. Learn to read between the lines and ask clarifying questions.

- #9 - Skipping Inspections: Not conducting FAI or third-party inspections to "save money" is penny-wise, pound-foolish.

- #10 - No Backup Plan: What if manufacturer goes bankrupt or quality fails? Have a Plan B manufacturer identified.

Frequently Asked Questions

When you source injection molds from China, plan for 10-16 weeks total: 1 week for quotes, 1 week for evaluation/negotiation, 6-10 weeks for mold production, 1-2 weeks for sampling/revisions, and 1-6 weeks for shipping (1 week air, 4-6 weeks sea). Add 2 weeks buffer for Chinese New Year if your timeline falls in January-February.

Most contracts include 1-2 rounds of revisions. Document issues clearly with photos and measurements. For steel-safe changes (adding material to part by removing mold steel), revisions are usually free or minimal cost. For steel-add changes (removing material from part), expect $500-$3,000 depending on extent. Typical revision turnaround is 1-2 weeks.

Highly recommended for orders over $50,000 or first-time relationships, but not mandatory. Many successful projects are managed 100% remotely using video calls, photo documentation, and third-party inspections. Virtual factory tours via video call are now standard and work well for most projects. In-person visits are valuable for building relationships and catching subtle red flags.

Use wire transfer (T/T) for established manufacturers with references. For first-time relationships or large orders, use Letter of Credit (provides bank guarantee) or escrow services. Never use Western Union, MoneyGram, or cryptocurrency. Never pay 100% upfront. Standard terms are 40-50% deposit, 30% at first article approval, 20-30% before shipment.

Your warranty clause should cover manufacturing defects for 300,000-500,000 shots. Document the issue immediately with photos and shot count. Contact manufacturer to discuss repair/replacement. This is why maintaining good relationships and clear contracts matters—reputable manufacturers will work with you to resolve issues. If manufacturer is unresponsive, warranty enforcement may require legal action, which is why choosing reputable manufacturers upfront is critical.

Yes, but it's often more practical to let manufacturer use their material for initial sampling. If you have specific resin requirements (particular grade, color, additives), you can either: (1) ship material to China (complex, customs issues), (2) specify exact grade and have them purchase locally (usually available), or (3) conduct final validation sampling at your molding facility in your country. Discuss this in the RFQ phase.

Post-delivery modifications are possible but expensive and time-consuming. For steel-safe changes (making part bigger by removing mold steel): $500-$2,000 plus 2-3 weeks. For steel-add changes (making part smaller by welding/adding mold steel): $2,000-$10,000 plus 3-4 weeks. Mold must be shipped back to China, modified, resampled, and shipped back. This is why thorough DFM review and moldflow analysis before tooling is so valuable.

Use a comprehensive NDA before sharing designs. Include IP ownership and non-compete clauses in your contract. For critical IP, file Chinese patents or trademarks. Work only with established manufacturers serving Western clients (they have more to lose). Consider watermarking CAD files. For highly sensitive products, split production across multiple manufacturers. Reality check: reputable manufacturers value their international reputation more than stealing one design. Focus on finding trustworthy partners through proper vetting.